Why Reality Capture Is Changing the Future of Construction

Explore how reality capture is reshaping construction by delivering accurate site data, minimizing rework, improving coordination, and supporting smarter project decisions.

Construction projects depend on accurate and current site information. Traditional workflows use drawings, manual surveys, and periodic inspections. These methods often capture incomplete or outdated conditions. Differences between design intent and actual site conditions create coordination issues. Teams face schedule delays, design revisions, and cost overruns. Reality capture addresses these challenges through direct digital site recording. It collects measurable spatial and visual data from real environments. This data reflects actual conditions instead of assumptions. As a result, project teams gain clearer visibility into site realities. Decision-making becomes based on factual information rather than interpretation.

Modern construction projects continue to grow in size and complexity, with increasing technical demands. Multidisciplinary coordination requires dependable spatial references. Reality capture for renovation provides consistent data throughout planning, construction, and closeout. Teams review site conditions without physical visits. Engineers validate dimensions directly from digital models. Project managers compare progress against design using visual records. These practices change traditional control methods. It supports data-driven project oversight. It establishes a reliable digital baseline for planning, coordination, and execution.

What Is Reality Capture in Construction

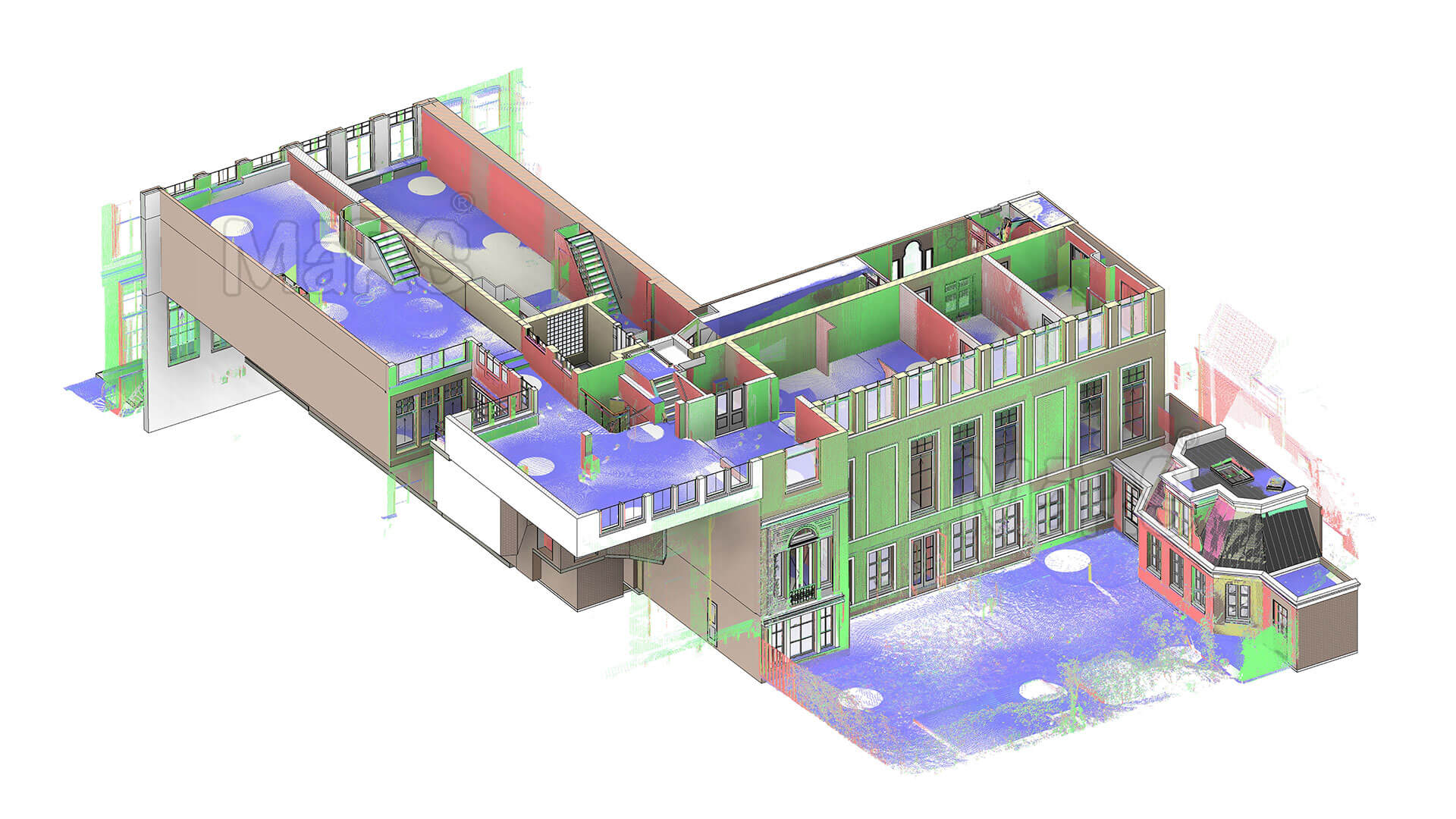

Reality capture in construction is the process of digitally recording physical site conditions. It uses scanning and imaging technologies to collect geometric and visual information. The collected data represents buildings, terrain, and installed systems. This information converts into structured digital formats. Common outputs include point clouds, surface meshes, and 3D models. Each output reflects existing site conditions at the time of capture. Teams use this data to review dimensions, locations, and spatial relationships. It replaces manual measurement methods with recorded site data.

Digital documentation supports project activities from early planning to handover. It documents existing conditions before design work begins. It records construction progress during execution. It produces accurate as-built information at project completion. The data integrates with CAD and BIM tools. All stakeholders access a single digital reference. This approach reduces interpretation differences and coordination gaps.

Key characteristics of data:

- Reflects actual site conditions at a specific time

- Supports CAD and BIM-based workflows

- Remote access to site information

- Provides consistent spatial reference for all teams

What Tools and Technologies Are Used?

3D Laser Scan in construction uses multiple technologies to collect spatial and visual data. Each tool serves a specific purpose based on project scale, accuracy needs, and site conditions. These technologies support data collection from ground level and aerial views. The captured information feeds into digital modeling and coordination workflows. Selection depends on required detail, access limitations, and project stage.

- 3D Laser Scanning: LiDAR Records precise geometry for structural and dimensional analysis.

- Photogrammetry: Produces surface geometry using image-based reconstruction methods.

- Drones: UAVs Capture large-area data from elevated viewpoints.

- 360-Degree Cameras: Document site context through panoramic visual records.

- BIM Integration: Transforms captured datasets into usable modeling formats.

Why Reality Capture Is Changing the Construction Industry

Advanced site scanning technology changes construction by providing verifiable site data at every stage. Traditional workflows depend on the interpretation of drawings and periodic checks. Advanced surveying technology provides location-specific measured conditions. This allows teams to validate layouts, tolerances, and system placement before work progresses. Conflicts between structure, MEP, and finishes appear early through spatial comparison. Issue resolution happens digitally instead of on-site. This reduces disruption to sequencing and trade coordination. Construction planning becomes more predictable and controlled.

It also alters how project information flows. Site data becomes available beyond physical boundaries. Design teams review conditions during active construction. Contractors document installations with time-stamped records. Project managers analyze progress using visual evidence instead of reports. Quality reviews link directly to captured conditions. These practices reduce ambiguity during approvals and reviews. Construction shifts toward data-backed coordination and measurable performance tracking.

Applications Across the Construction Lifecycle

Site Survey and Existing Conditions

Site survey records terrain, structures, and utilities as measured data. Survey teams extract dimensions, elevations, and clearances directly from point clouds, reducing field visits and improving baseline accuracy for planning.

Design and Preconstruction Planning

Captured site data informs layouts, levels, and constraints during preconstruction. Designers reference current conditions to validate assumptions, adjust geometry, and reduce revisions before permits, procurement, and construction sequencing reviews.

Clash Detection and Coordination

Spatial comparisons between captured data and models expose conflicts across structure and MEP. Teams resolve interferences digitally, limiting rework, trade delays, and installation changes before fabrication and site activities begin.

Construction Progress Tracking

Periodic scans capture installed work at milestones. Managers compare quantities, locations, and sequencing against plans, identifying deviations early and adjusting workflows without disrupting ongoing operations across multiple site zones simultaneously.

Visual timelines align as-built conditions with design intent. Teams review progress through dated models, supporting transparent reporting, stakeholder reviews, and schedule discussions based on observed conditions across project phases consistently.

Quality Control and Compliance

Captured evidence validates installed work against specifications. Inspectors confirm tolerances, routing, and clearances digitally, supporting audits, claims resolution, and acceptance decisions with traceable records through time-stamped site captures and approvals.

Final Handover and Facility Management

As-built models and point clouds transfer to operations teams. Facilities access geometry, locations, and context for maintenance, renovations, and future planning across asset lifecycles with reduced site visits and downtime.

The Future of Reality Capture in Construction

Reality capture will move from supporting individual projects to becoming a core part of digital construction ecosystems. AI-powered scanning will automatically detect building components, flag deviations, and suggest design corrections. Multi-sensor drones will capture complex environments faster, including interiors, exteriors, and underground spaces. Integration with augmented and virtual reality will allow teams to simulate construction sequences before work begins. Advanced analytics will convert point clouds into actionable insights for cost forecasting, risk assessment, and sustainability analysis. Smaller firms will gain access to affordable scanning hardware and cloud-based processing. Captured data will transform from reference material into dynamic decision-making tools, guiding projects from design through long-term facility operation.

Conclusion

Reality capture is reshaping construction by turning physical sites into precise digital models. It provides actionable insights that improve planning, design accuracy, and project monitoring. By capturing real-world conditions at every stage, teams reduce conflicts, track progress visually, and manage costs more effectively. Emerging technologies such as AI-assisted scanning, drones, and digital twins will expand their role across project lifecycles. As adoption grows, It will become a standard operational tool, enabling construction teams to base decisions on reliable, measurable data rather than assumptions.