Why Is a Glass Washing Machine Essential for High-Quality Glass Processing?

Whether the glass is used for architectural facades, automotive windshields, interior décor, or electronic applications, even the smallest impurity can reduce its value and performance. This is where a glass washing machine becomes an essential part of modern glass machinery.

In today’s competitive glass manufacturing industry, quality is not optional—it is mandatory. Whether the glass is used for architectural facades, automotive windshields, interior décor, or electronic applications, even the smallest impurity can reduce its value and performance. This is where a glass washing machine becomes an essential part of modern glass machinery.

A glass washing machine ensures that glass surfaces are perfectly clean, residue-free, and ready for further processing such as tempering, laminating, coating, or printing. Without proper washing and drying, scratches, watermarks, dust particles, and chemical residues can compromise the final output. In this detailed guide, we will explore why a glass washing machine is critical for high-quality glass processing, how it works, its benefits, and how it integrates with other machines like glass drilling machines and glass edging machines.

What Is a Glass Washing Machine?

A glass washing machine is an industrial machine designed to clean, rinse, and dry glass sheets or panels after they undergo processes such as cutting, edging, drilling, or grinding. During these processes, glass accumulates glass powder, oil, fingerprints, and abrasive residues that must be removed before further treatment.

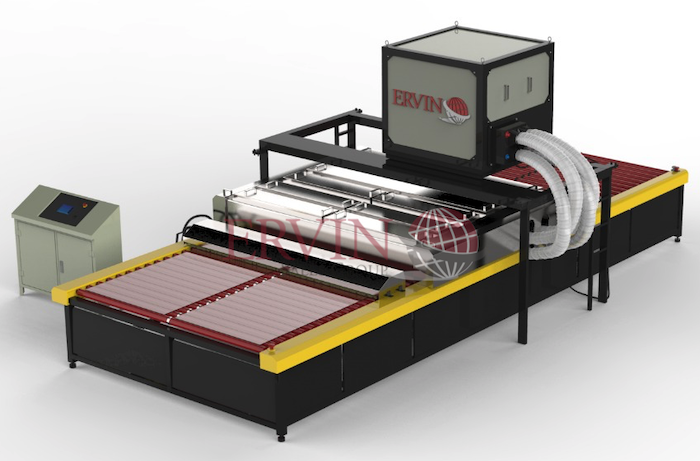

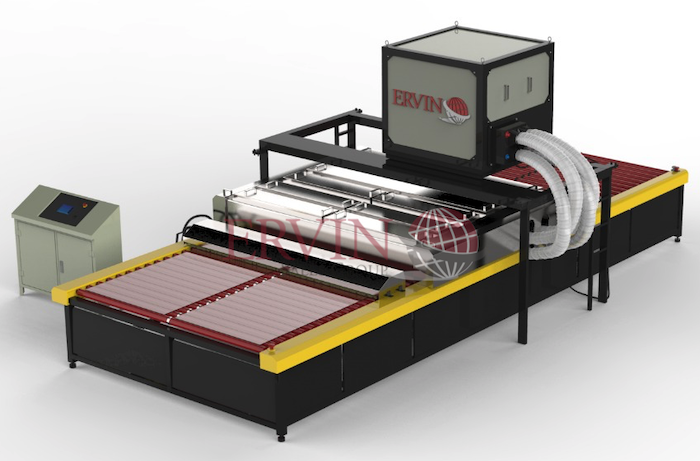

Modern glass washing machines use a combination of high-pressure water sprays, rotating brushes, purified water systems, and hot air drying units. These machines are available in different configurations depending on glass thickness, size, and production volume. From small workshops to large-scale factories, the glass washing machine is a core element of professional glass processing lines.

Why Clean Glass Is Critical in Glass Processing

Cleanliness plays a vital role in the structural integrity, appearance, and performance of glass products. When glass surfaces are not washed properly, contaminants remain trapped and create long-term issues.

Dust or residue on glass can cause:

- Poor adhesion during lamination or coating

- Visible stains after tempering

- Scratches during stacking or transport

- Rejection by clients due to quality defects

A high-quality glass washing machine eliminates these risks by delivering consistent and repeatable cleaning results. This level of precision is impossible to achieve through manual washing, especially in industrial environments.

Role of a Glass Washing Machine in High-Quality Glass Production

A glass washing machine is not just a cleaning tool—it is a quality control machine. It ensures that every glass panel entering the next stage of production meets strict cleanliness standards.

In industries like architecture and automotive manufacturing, even microscopic impurities can result in optical distortion or structural weakness. By using an advanced glass washing machine, manufacturers ensure:

- Uniform surface cleanliness

- Reduced defect rates

- Improved durability of finished glass

This directly enhances customer satisfaction and strengthens brand reputation.

Integration with Other Glass Machinery

Modern glass factories rely on a complete glass machinery ecosystem. A glass washing machine works in close coordination with machines such as the glass edging machine, glass drilling machine, and cutting tables.

After edging or drilling, glass surfaces are covered with cooling fluids and fine glass dust. If these residues are not removed, they interfere with downstream processes. Installing a glass washing machine between these stages ensures seamless workflow and higher production efficiency.

Importance After Glass Edging Operations

A glass edging machine smooths sharp edges and improves safety and appearance. However, edging creates fine particles and slurry that cling to the glass surface.

Without proper washing:

- Edging residues harden and stain the glass

- Surface clarity is reduced

- Glass becomes unsuitable for premium applications

A glass washing machine removes all edging residues, ensuring the glass is visually flawless and ready for further processing like tempering or coating.

Why Glass Washing Is Essential After Glass Drilling

A glass drilling machine creates holes for fittings, handles, or mounting systems. Drilling involves lubrication oils and fine debris that remain around holes and surfaces.

If glass is not washed immediately:

- Oil stains become permanent

- Holes may crack during tempering

- Structural weakness increases

Using a glass washing machine after drilling ensures clean holes, residue-free surfaces, and improved mechanical strength.

How a Glass Washing Machine Works

A standard glass washing machine operates in multiple stages:

- Pre-Wash Section – Removes loose dust and debris

- Brushing Section – Rotating soft or hard brushes scrub the glass surface

- Rinsing Section – Purified or demineralized water removes remaining contaminants

- Drying Section – Hot air blowers dry the glass without watermarks

Advanced machines allow adjustable pressure, brush speed, and temperature, making them suitable for different glass types and thicknesses.

Key Benefits of Using a Glass Washing Machine

1. Superior Glass Quality

A glass washing machine ensures crystal-clear glass surfaces, improving both appearance and performance.

2. Reduced Rejection Rates

Clean glass significantly lowers defects, saving money on rework and waste.

3. Enhanced Processing Efficiency

When integrated with other glass machinery, washing machines streamline production flow.

4. Consistent Results

Unlike manual washing, machines provide uniform quality across batches.

5. Increased Product Value

High-quality washed glass commands better pricing and customer trust.

Types of Glass Washing Machines

Different applications require different machine configurations. Below is a comparison table to help understand common types:

| Type of Glass Washing Machine | Application Area | Key Features |

|---|---|---|

| Vertical Glass Washing Machine | Architectural & automotive glass | Space-saving, high throughput |

| Horizontal Glass Washing Machine | Flat & processed glass | Stable handling, large glass sizes |

| Low-E Glass Washing Machine | Coated glass | Soft brushes, no surface damage |

| Solar Glass Washing Machine | Solar panel manufacturing | Ultra-pure water system |

| Automatic Glass Washing Machine | Large factories | PLC control, minimal labor |

Choosing the Best Glass Washing Machine for Your Business

Selecting the best glass washing machine depends on several factors:

- Glass size and thickness

- Production volume

- Type of glass (clear, coated, laminated)

- Integration with existing glass machinery

Investing in the right machine ensures long-term productivity, lower maintenance costs, and superior output quality.

Energy Efficiency and Water Management

Modern glass washing machines are designed with energy-efficient motors and water recycling systems. These features reduce operational costs while maintaining high cleaning standards.

Advanced systems use:

- Filtered and reused water

- Low-consumption blowers

- Automated shutdown mechanisms

This makes the glass washing machine both economical and environmentally friendly.

Impact on Tempering and Laminating Quality

Before glass enters a tempering furnace or lamination line, surface cleanliness is critical. Any impurity can cause:

- Optical distortion

- Delamination

- Surface burns

A glass washing machine ensures that the glass surface is perfectly prepared, resulting in stronger, safer, and longer-lasting glass products.

Maintenance and Longevity of Glass Washing Machines

Regular maintenance ensures optimal performance. Key maintenance practices include:

- Cleaning brushes and rollers

- Checking water filters

- Inspecting blowers and heaters

With proper care, a high-quality glass washing machine can operate efficiently for many years.

Future Trends in Glass Washing Technology

The glass industry is moving toward automation and smart manufacturing. New glass washing machines feature:

- AI-based defect detection

- Touchscreen control panels

- IoT-enabled performance monitoring

These innovations further improve efficiency and quality in glass processing plants.

Conclusion: Why a Glass Washing Machine Is Non-Negotiable

In high-quality glass processing, a glass washing machine is not an optional accessory—it is a necessity. From improving surface clarity to enhancing compatibility with other glass machinery like glass edging machines and glass drilling machines, its role is indispensable.

Manufacturers who invest in the best glass washing machine gain a competitive edge through superior quality, reduced waste, and increased customer satisfaction. In an industry where precision defines success, clean glass is the foundation—and a glass washing machine makes it possible.

Frequently Asked Questions (FAQs)

1. Why is a glass washing machine important in glass manufacturing?

A glass washing machine removes dust, oil, and residues, ensuring high-quality, defect-free glass for further processing.

2. Can a glass washing machine handle different glass thicknesses?

Yes, modern machines are adjustable and can handle a wide range of glass thicknesses and sizes.

3. Is a glass washing machine required after glass edging?

Absolutely. After using a glass edging machine, washing is essential to remove slurry and abrasive particles.

4. What makes the best glass washing machine?

The best glass washing machine offers efficient cleaning, energy savings, adjustable settings, and seamless integration with other glass machinery.

5. How often should a glass washing machine be maintained?

Routine maintenance should be done weekly, with detailed inspections scheduled monthly for optimal performance.

Ervin Sales Group – The Best Glass Machinery Supplier in USA

Ervin Sales Group is your complete supplier for glass machinery and glass accessories.

ERVIN Sales Group has offices Located in Northern California and supplies product to the U.S., Canada, and Mexico.

Contact:

ERVIN, Inc. 13116 Lincoln Way #3138 Auburn, CA 95604 Ph: 9169338367 Email: sales@ervinsales.com

Visit Now: https://www.ervinsales.com/