What Is a Control Valve Seat Leakage Classification?

What Is a Control Valve Seat Leakage Classification?

Introduction

Control valves are essential for regulating fluid flow across a wide range of industrial applications. While many valve types offer precise modulation and reliable shut-off in clean service, controlling fluids containing solids—such as slurries—poses far greater challenges. In abrasive service, no valve design is perfect, and achieving both precise flow control and effective shut-off becomes increasingly difficult.

Although standard control valves may deliver tight shut-off when new, exposure to abrasive media quickly erodes internal surfaces, leading to leakage shortly after commissioning. Consequently, it's not common industry practice to rely on a control valve alone for both modulation and isolation in slurry systems. Most manufacturers recommend pairing the control valve with a dedicated on/off valve to ensure proper system isolation when required.

In slurry service, metal-seated control valves often allow a measurable amount of leakage when fully closed. This leakage is defined by standardized classification levels, from Class I to Class VI. Notably, Class V and VI shut-off ratings are generally associated with resilient-seated isolation valves (e.g., rubber or urethane). Control valves claiming Class V shut-off in abrasive service usually degrade to Class IV or lower due to wear.

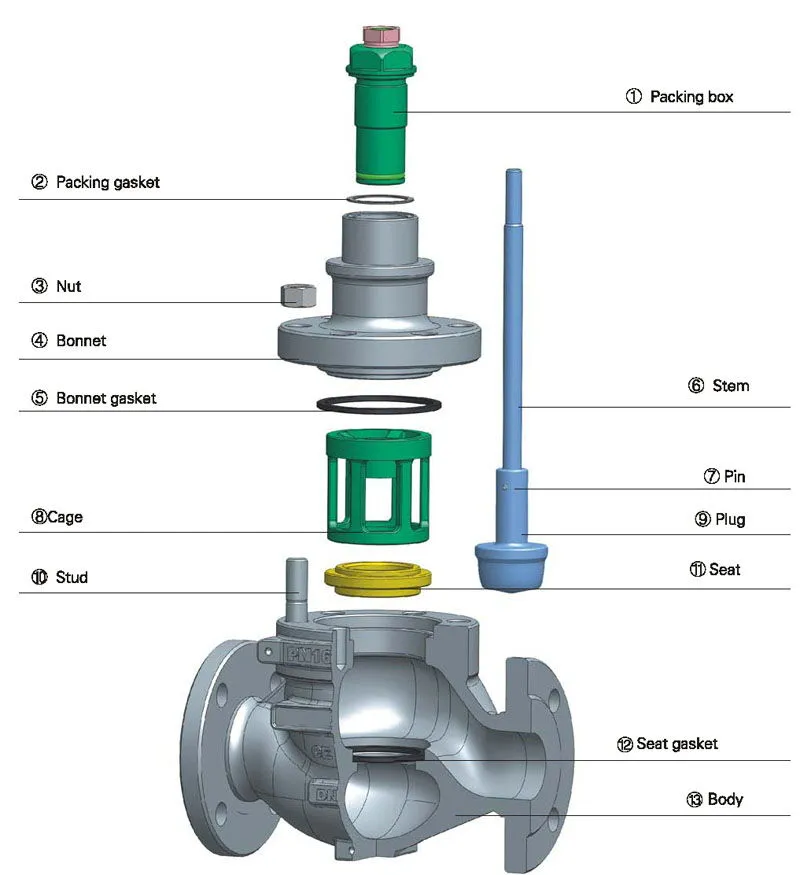

Drawing for Pneumatic Single-Seat Control Valve (Placeholder for diagram if applicable.)

Understanding Leakage Classifications

Control valve seat leakage classifications help users evaluate how effectively a valve prevents fluid flow when fully closed. These standards, established by organizations such as ANSI and ISO, serve as benchmarks for valve performance across different operating conditions.

Leakage Classes Overview:

- Class I – Non-tight shut-off: Minimal design considerations for leakage control. Acceptable in non-critical applications.

- Class II – Basic shut-off: Moderate leakage reduction over Class I; used where some leakage is tolerable.

- Class III – Improved shut-off: Common in systems where moderate sealing is required but minor leakage is acceptable.

- Class IV – Tight shut-off: Suitable for many industrial applications, including metal-seated slurry valves. Balances durability and leak control.

- Class V – Very tight shut-off: Designed for isolation duties in clean fluid service. Difficult to achieve in metal-seated valves used with abrasive fluids.

- Class VI – Bubble-tight shut-off: Highest sealing performance, typically with soft (resilient) seat materials. Ideal for sanitary or sensitive systems (e.g., pharmaceuticals, food and beverage).

Key Industry Standards for Valve Leakage and Testing

Several industry standards govern valve design, testing, and classification:

- ASME B16.34 – Covers valve pressure ratings and materials but does not define leakage levels. Often used alongside API 598.

- API 598 – Specifies inspection and testing criteria, including leakage limits for both metal- and resilient-seated isolation valves.

- MSS SP61 – An earlier standard for hydrostatic testing of steel valves; less commonly used today but historically influential.

- ISO 5208 – Defines leakage rates and test methods across ten leakage rate levels; often used in international projects.

- ANSI FCI 70-2 – Defines Classes I–VI leakage levels specifically for control valves. Widely referenced for internal seat leakage testing.

- ISA S75 – Focuses on hydrostatic testing procedures for control valves, often referencing FCI 70-2 for leakage classification.

These standards ensure that valves meet reliability, safety, and performance expectations in critical applications.

Factors Affecting Leakage Performance

Leakage performance is influenced by a combination of design, materials, operating environment, and maintenance practices:

- Valve Design: Sealing mechanisms and seat configurations (e.g., metal vs. soft seat) significantly impact leak rates and wear resistance.

- Material Selection: Hard-faced or abrasion-resistant materials improve longevity in slurry applications but may still suffer erosion over time.

- Operating Conditions: Pressure, temperature, and the nature of the fluid (abrasive, corrosive, etc.) directly affect seal performance and durability.

- Maintenance & Wear: Even well-designed valves degrade over time in abrasive service. Periodic inspection and maintenance are essential to sustain sealing performance.

Choosing the Right Valve for Your Application

Selecting a control valve requires balancing control precision, shut-off performance, and operational durability. Key recommendations:

- Clean Fluids: Use valves rated for Class V or VI shut-off to achieve both control and isolation, especially in critical systems.

- Slurry Applications: Opt for metal-seated control valves with Class IV leakage classification. Install a separate on/off valve for complete isolation.

- High-Stakes Applications: In pharmaceutical, food, or high-purity processes, Class VI bubble-tight resilient-seated valves are preferred.

Conclusion

Understanding control valve seat leakage classifications is essential for making informed decisions in process design and equipment selection. While clean fluid applications can often meet both tight shut-off and accurate control requirements, slurry and abrasive service demand a more nuanced approach.

In such challenging environments, metal-seated valves with Class IV leakage are typically the best compromise between performance and durability. However, isolation should be managed by a separate valve, as even the best control valves are likely to leak over time.

Engineers and operators who grasp the limitations and classifications of valve leakage can design more reliable systems, reduce downtime, and extend the service life of critical components.