What Are Pall Rings? A Complete Guide to Their Design, Function, and Applications

An introductory yet detailed overview explaining how Pall Rings work in mass transfer processes.

Mass transfer efficiency is a critical factor in many industrial separation processes, including distillation, absorption, stripping, and scrubbing. One of the most widely used solutions to enhance mass transfer in packed columns is Pall Rings. Their innovative design offers superior performance compared to traditional packing materials, making them a preferred choice across chemical, petrochemical, and environmental industries.

This article provides an introductory yet detailed explanation of what Pall Rings are, how they work, and why they are effective in mass transfer operations.

What Are Pall Rings?

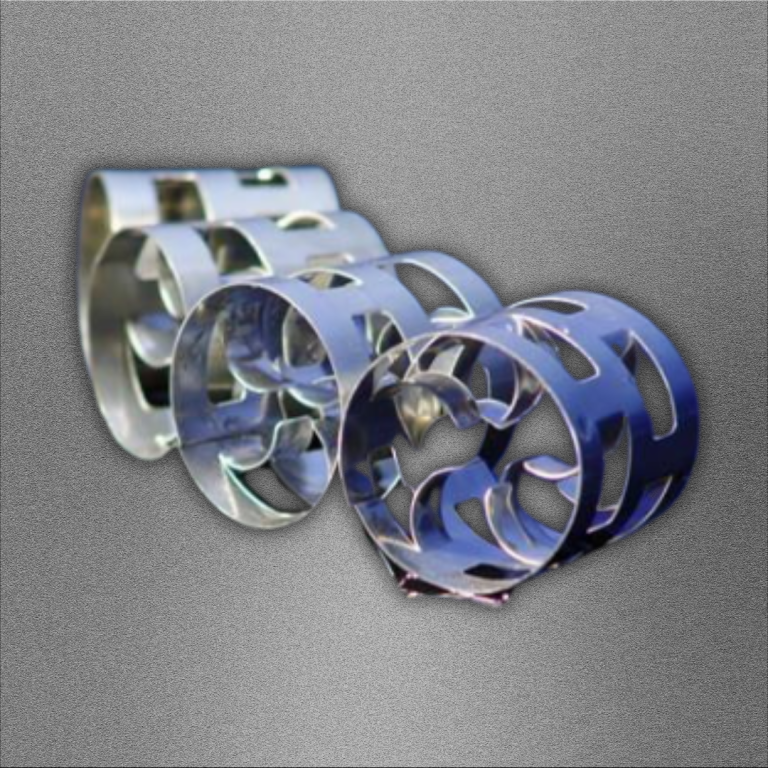

Pall Rings are a type of random packing used in packed columns to improve contact between gas and liquid phases. They are an advanced version of Raschig Rings, designed with open cylindrical structures and internal tabs or windows that significantly increase surface area while maintaining a low pressure drop.

Pall Rings are manufactured from a variety of materials, including:

- Plastic (PP, PVC, PVDF)

- Metal (stainless steel, carbon steel)

- Ceramic

Each material is selected based on process conditions such as temperature, pressure, and chemical compatibility.

The Role of Packing in Mass Transfer

In mass transfer operations, efficient exchange of components between phases depends on maximizing contact area and maintaining proper fluid flow. Packing materials inside a column serve several important functions:

- Increase surface area for gas-liquid interaction

- Promote uniform liquid distribution

- Reduce channeling and flooding

- Minimize pressure drop across the column

Pall Rings excel in all these areas due to their optimized geometry.

How Pall Rings Work in Mass Transfer Processes

1. Increased Surface Area for Contact

The defining feature of Pall Rings is their open structure with internal ligaments. These elements create a large effective surface area where the liquid spreads as a thin film. When gas flows upward through the column, it contacts this liquid film, allowing mass transfer to occur efficiently.

Greater surface area means:

- Faster transfer of components

- Improved separation efficiency

- Reduced column height requirements

2. Enhanced Turbulence and Mixing

Unlike simple cylindrical packings, Pall Rings disrupt both gas and liquid flow paths. Their internal tabs create controlled turbulence, which continuously renews the liquid film on the packing surface.

This turbulence:

- Prevents stagnant zones

- Improves mass transfer coefficients

- Enhances overall column performance

3. Uniform Liquid Distribution

One of the major challenges in packed columns is liquid channeling, where fluid flows unevenly through the bed. Pall Rings help prevent this by redistributing liquid as it cascades from one ring to another.

This results in:

- Consistent wetting of the packing

- Stable operation across varying flow rates

- Improved process reliability

4. Low Pressure Drop

Despite offering high surface area, Pall Rings maintain a low pressure drop due to their open geometry. The large void fraction allows gas to flow freely, reducing energy consumption and operating costs.

Low pressure drop is especially important in:

- Vacuum distillation

- Gas absorption systems

- Large-scale industrial columns

Applications of Pall Rings in Mass Transfer

Pall Rings are used in a wide range of mass transfer operations, including:

- Distillation columns

- Gas absorption and stripping towers

- Scrubbers and air pollution control systems

- Wastewater treatment processes

- Chemical and petrochemical processing units

Their adaptability makes them suitable for both high-capacity and precision separation systems.

Why Choose Pall Rings Over Traditional Packings?

Compared to older packing types such as Raschig Rings, Pall Rings offer:

- Higher efficiency per unit volume

- Better liquid distribution

- Reduced pressure drop

- Improved operational flexibility

These advantages often translate into smaller column sizes, lower operating costs, and higher throughput.

Conclusion

Pall Rings play a crucial role in enhancing mass transfer by maximizing surface area, improving flow dynamics, and maintaining low pressure drop. Their advanced design makes them an ideal choice for modern packed columns across a variety of industries.

Whether used in distillation, absorption, or environmental applications, Pall Rings provide a reliable and cost-effective solution for achieving high-efficiency mass transfer.