Thyristor Diode Modules vs IGBT: Key Differences Explained

Discover key differences between thyristor diode modules and IGBTs to choose the right power electronics for your system’s efficiency and control needs.

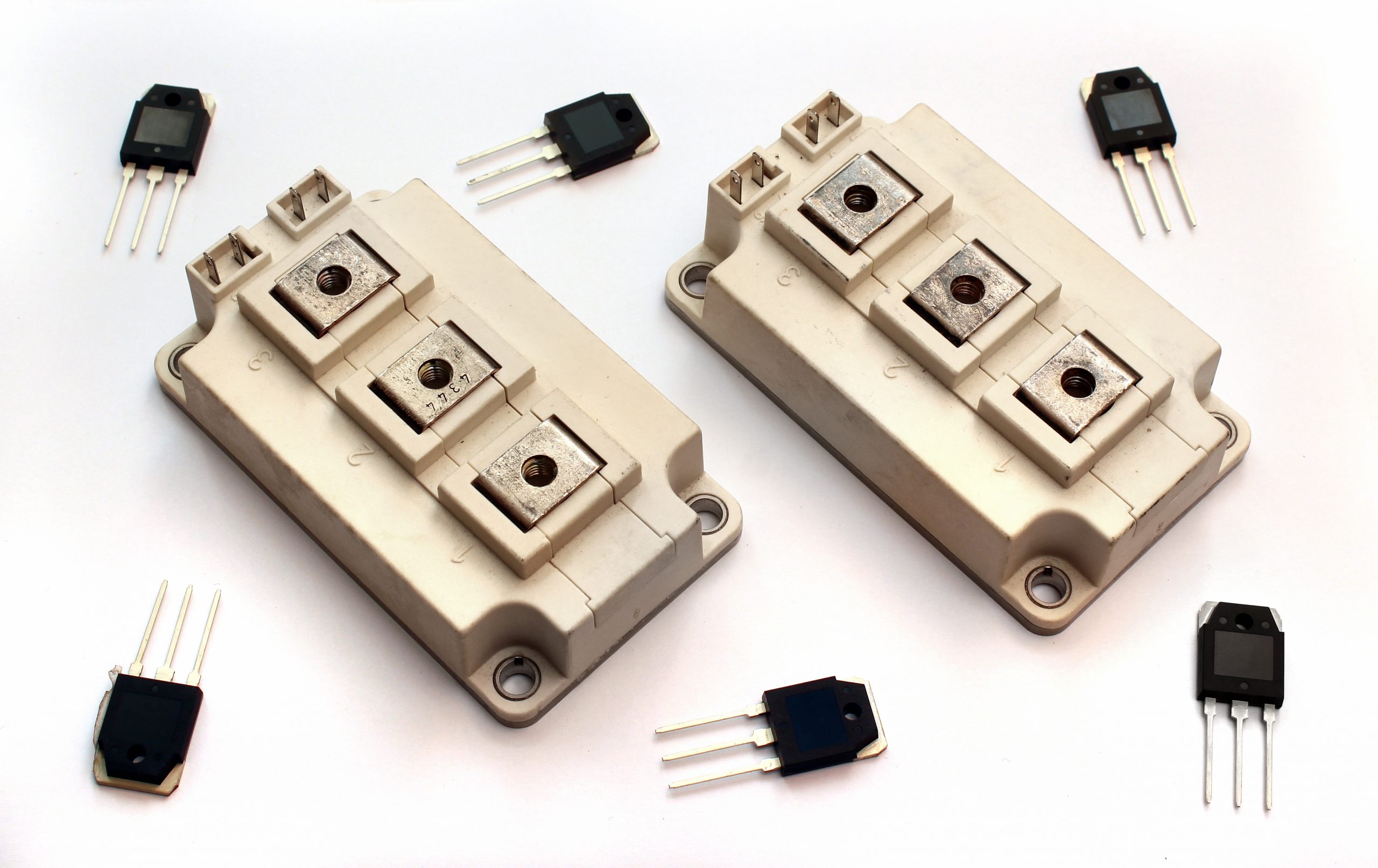

When it comes to power electronics, selecting the right component can significantly impact how your system performs. Two of the most commonly used technologies in high-power applications are thyristor diode modules and IGBT modules. While both are built to handle heavy electrical loads, they function quite differently and are suited for distinct types of systems.

In this article, we’ll walk you through what sets them apart, where each one shines, and how to make the right choice based on your project’s needs.

Getting to Know the Basics

Before we explore the differences, let’s take a closer look at what these two modules are and their intended purposes.

Thyristor Diode Modules

These modules typically integrate a thyristor and a diode into a single package. A thyristor acts as a switch that is activated when triggered and remains active until the current falls below a certain level. It's ideal for systems that deal with steady, high-voltage conditions. When paired with a diode module, this setup is perfect for controlling the direction and timing of current flow in high-power applications, such as AC/DC converters, soft starters, and motor drives.

IGBT Modules

The Insulated Gate Bipolar Transistor (IGBT) is a modern semiconductor device that controls and amplifies electrical signals. What sets IGBTs apart is their rapid response and the level of control they offer over power flow. This makes them especially popular in systems that require quick and efficient switching, such as inverters, electric cars, and renewable energy setups.

How They Work Differently

The key difference lies in how each component controls current:

- Thyristor modules need a gate signal to turn on, but once they’re conducting, they stay on until the current naturally stops flowing. This makes them ideal for systems where rapid on/off switching is not required.

- IGBT modules, on the other hand, offer complete control over the current. You can turn them on and off with ease by adjusting the gate signal. This level of control is instrumental in systems where the power needs to be modulated quickly and efficiently.

Performance & Applications: Where Each One Fits

Where Thyristor Diode Modules Excel:

These modules are often used in industries where simple control and high power are more important than switching speed. You'll commonly find them in:

- Controlled rectifiers

- AC motor soft starters

- Static VAR compensators

- Welding equipment

- High-voltage DC transmission systems

Since these modules are rugged and can handle high voltage without complex circuitry, they're ideal for large-scale industrial systems.

Where IGBT Modules Lead the Way:

The IGBT module is better suited for advanced systems that demand precision and responsiveness. Some key application areas include:

- Variable frequency drives (VFDs)

- Solar and wind inverters

- Traction systems in electric trains

- Electric vehicle powertrains

- UPS and battery storage systems

These applications benefit from the IGBT’s ability to switch quickly and deliver power efficiently without generating excessive heat.

Efficiency, Cost, and Control

If you’re looking at efficiency in fast-changing conditions, IGBTs tend to perform better. They switch more quickly and waste less energy, making them a solid choice for systems where power conservation is crucial.

On the other hand, thyristor modules are generally more cost-effective. They don’t need complex control setups, which keeps installation and upkeep simple. That said, they don’t offer the same level of precision or speed when switching. It’s all about weighing cost against control.

In terms of control, it’s all about what you need. If your system requires flexibility and frequent changes in power delivery, go with an IGBT module. If you’re looking for stability and can work with slower switching speeds, thyristor diode modules might be a better fit.

Which One Should You Choose?

There is no one-size-fits-all answer here; it depends on your specific application. Ask yourself:

Do I need high-speed switching or just solid power control? Is efficiency or simplicity more critical in my setup? Am I working with advanced electronics, or is my system more traditional?

If you're still unsure, it’s always best to consult a specialist or reach out to a trusted supplier who understands both thyristor modules and IGBT modules and can guide you based on real-world needs.

Final Thoughts

Thyristor diode modules and IGBT modules each bring their strengths to power electronics. Understanding how they function and where they perform best can help you make more informed, practical choices for your system. The proper selection not only improves performance and efficiency but also reduces long-term maintenance and costs.

To achieve the best results, always opt for trusted manufacturers and ensure the component meets your specific needs. A thoughtful decision now can lead to fewer issues and better returns in the long run.