Stainless Steel 321H Pipes: High-Temperature Strength with Enhanced Stability

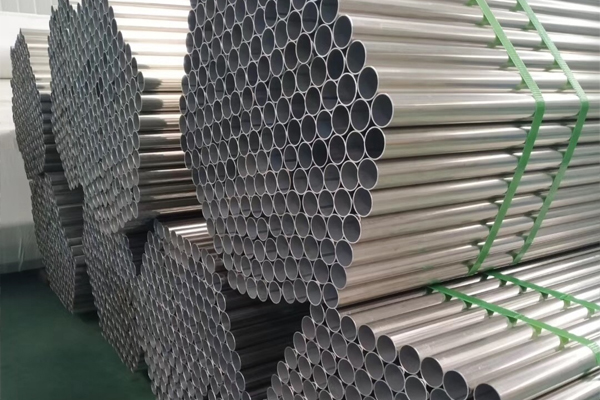

Stainless Steel 321H Pipes offered by A M Industries epitomize the perfect blend of excellent performance and reliability for several industrial applications.

Introduction

Stainless Steel 321H Pipes are high-performance piping solutions specifically designed for elevated temperature service. A stabilized austenitic stainless steel, 321H is an enhanced version of SS 321 with a higher carbon content, which improves its high-temperature strength and creep resistance. These pipes are widely used in heat exchangers, refinery equipment, high-pressure systems, and aerospace applications where thermal stability is critical.

Understanding Grade 321H Stainless Steel

Grade 321H (UNS S32109) is a high-carbon variant of Stainless Steel 321. Both grades are titanium-stabilized, which helps prevent intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range (427–816°C / 800–1500°F). The key difference lies in the carbon content:

- SS 321 Carbon Content: ≤ 0.08%

- SS 321H Carbon Content: 0.04–0.10%

This higher carbon level in 321H makes it suitable for structural applications at higher temperatures.

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.04–0.10 |

| Chromium (Cr) | 17.0–19.0 |

| Nickel (Ni) | 9.0–12.0 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Titanium (Ti) | ≥ 5 × C% (min) |

Key Properties of SS 321H Pipes

1. High-Temperature Resistance

321H pipes offer outstanding performance at temperatures up to 900°C (1652°F), making them ideal for thermal processing environments and elevated-temperature structural applications.

2. Excellent Creep Strength

The increased carbon content enhances resistance to stress rupture and creep deformation under prolonged heat exposure.

3. Resistance to Oxidation and Corrosion

These pipes are highly resistant to oxidation and scaling at high temperatures and show moderate corrosion resistance in various environments.

4. Stabilization with Titanium

Titanium stabilizes the structure, preventing sensitization during welding and extended heating, which enhances durability and longevity.

Applications of Stainless Steel 321H Pipes

Thanks to their thermal and mechanical stability, SS 321H pipes are widely used in:

- Petrochemical refineries

- Heat exchangers and boilers

- Furnace components

- High-temperature chemical processing

- Aerospace engine parts

- Nuclear power plant components

- Superheaters and reheaters

Available Forms & Specifications

SS 321H Pipes are available in several forms to meet industry needs:

- Seamless & Welded Pipes

- ERW (Electric Resistance Welded)

- EFW (Electric Fusion Welded)

- Round, square, and rectangular configurations

Standards & Specifications:

- ASTM A312 / A358

- ASME SA312 / SA358

- DIN, EN, and JIS equivalents

Advantages of SS 321H Pipes

- Superior performance in high-temperature service

- Excellent weldability and formability

- Strong resistance to intergranular corrosion

- Long service life and low maintenance

- Cost-effective alternative to nickel alloys for many high-temperature applications

Conclusion

Stainless Steel 321H Pipes combine the stability of titanium-stabilized stainless steel with the strength provided by higher carbon content, making them an ideal choice for high-temperature, high-pressure environments. Their reliability, durability, and excellent mechanical properties ensure long-term performance in demanding industries such as oil and gas, power generation, and chemical processing.

If your application involves high temperatures and mechanical stress, SS 321H is a material that delivers both peace of mind and performance.