Soft Gripping Innovation: Redefining Precision and Flexibility in Industrial Automation

Soft gripping technology is no longer limited to a single sector. In food processing, Soft Grippers handle fruits and vegetables without bruising.

In today’s rapidly evolving automation landscape, flexibility and precision are no longer optional—they are essential. Traditional rigid gripping systems are being replaced by adaptive solutions that can handle delicate, irregular, or variable objects with ease. At the heart of this transformation lies the**** Soft Gripper, a technology redefining how robots interact with the physical world.

Understanding Soft Gripping Technology

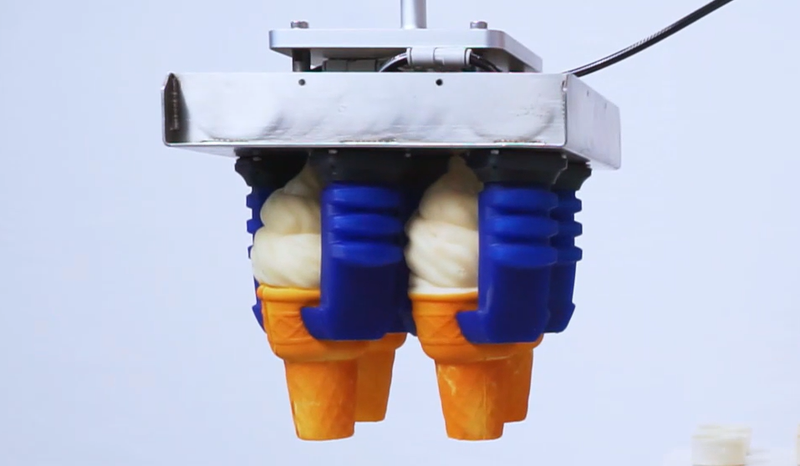

A Soft Gripper is designed using compliant materials that mimic the adaptability of the human hand. Unlike rigid claws, these systems can conform to different shapes, textures, and sizes without damaging the product. This capability makes them ideal for industries such as food processing, pharmaceuticals, logistics, agriculture, and electronics.

The rise of Soft Grippers**** is closely tied to advancements in material science and artificial intelligence. Companies like Soft Robotics Inc**** have played a major role in popularizing these solutions, demonstrating that soft automation can significantly improve efficiency while reducing waste and downtime.

Why Soft Grippers Are in High Demand

One of the biggest advantages of Soft Grippers is their versatility. They can handle fragile items such as fruits, baked goods, medical devices, and electronic components. This has positioned the Soft Robot Gripper as a preferred choice in environments where product integrity is critical.

Another reason for their popularity is safety. A Robot Soft Gripper minimizes the risk of injury when humans and robots work side by side. This makes collaborative robotics more feasible and cost-effective, especially for small and medium-sized manufacturers.

Innovations in Soft Robotics

Modern automation increasingly relies on the Soft Robotics Gripper, which integrates sensors and adaptive control systems. These grippers can adjust force in real time, ensuring consistent performance even when object size or weight changes. As a result, many manufacturers now consider the Best Soft Robot Gripper to be a long-term investment rather than a niche solution.

A key component of these systems is the Soft Robotic Finger, which bends and flexes using air pressure or other actuation methods. These fingers replicate natural motion, enabling robots to grasp complex objects that were once impossible to automate.

Pneumatic Power and Precision

Most soft gripping systems operate using pneumatic technology. A Pneumatic Gripper uses compressed air to control movement, offering reliability and simple maintenance. When combined with flexible materials, this results in the highly efficient Soft Pneumatic Gripper, capable of fast cycle times and gentle handling.

For applications requiring pick-and-place operations on flat or smooth surfaces, the Soft Robotics Suction Cup provides an effective solution. These suction-based systems excel in packaging and sorting lines, where speed and adaptability are crucial.

Choosing the Right Soft Robotics Partner

Selecting the right supplier is just as important as choosing the technology itself. A reliable Soft Robotics Solutions Supplier not only delivers high-quality hardware but also provides integration support, customization, and after-sales service. Businesses looking to scale their automation efforts often seek the Best Soft Gripper Manufacturer to ensure long-term performance and return on investment.

This is where**** SRT Soft Gripper has established a strong reputation in the market. By focusing on innovation, quality materials, and customer-centric design, the company addresses the real-world challenges faced by modern manufacturers. Its product portfolio, including the Srt Soft Robot Gripper, reflects a commitment to precision, durability, and adaptability.

Applications Across Industries

Soft gripping technology is no longer limited to a single sector. In food processing, Soft Grippers handle fruits and vegetables without bruising. In e-commerce and logistics, they enable faster sorting of diverse packages. In healthcare and laboratories, the Soft Robot Gripper ensures sterile and damage-free handling of sensitive instruments.

Electronics manufacturers also benefit from the Soft Robotics Gripper, as it reduces the risk of scratching or breaking delicate components. These advantages collectively explain why soft robotics is one of the fastest-growing segments in industrial automation.

The Road Ahead

As automation continues to evolve, soft gripping solutions will play an even greater role. Advances in AI, sensor integration, and materials will further enhance the capabilities of Soft Grippers, making them smarter and more responsive. Businesses that adopt these technologies early will gain a competitive edge through improved efficiency, reduced waste, and enhanced product quality.

In conclusion, soft gripping technology represents a shift toward more human-like, adaptable automation. With industry leaders, innovative designs, and trusted providers like SRT Soft Gripper, the future of robotics is not just powerful—it’s gentle, intelligent, and remarkably flexible.