Linear Motion: Types, Principles, and Applications

Discover the types, principles, and real-world applications of linear motion and see how Linear Motor delivers precision, speed, and reliability in every move.

Linear motion defines the precision heartbeat of today’s automated world. From semiconductor manufacturing to medical diagnostics, industries rely on smooth, accurate, and repeatable motion to push innovation forward. At the core of these advancements lies the power of linear motors, direct-drive solutions that eliminate friction, enhance responsiveness, and redefine efficiency. Among the leaders in this field, ITG Linear Motor stands out with its cutting-edge technology engineered for uncompromising accuracy and long-term reliability across diverse applications.

What Is Linear Motion?

Linear motion, at its core, refers to movement along a straight path unlike rotational motion, which follows a circular trajectory. It is one of the most fundamental types of motion in physics and engineering, forming the backbone of countless industrial and automation systems. Any time an object moves from one point to another in a straight line, whether it’s a robotic arm positioning a component or a precision stage moving a wafer, linear motion is at work.

In mechanical systems, linear motion is typically achieved by converting rotary motion (from a motor or actuator) into linear displacement using components such as ball screws, belts, or gears. However, these traditional transmission mechanisms introduce friction, backlash, and wear over time, which can affect accuracy and reliability, especially in high-precision applications.

What Is Linear Motion?

To overcome these limitations, modern industries increasingly adopt linear motor technology, which generates direct linear force without mechanical conversion. This means the moving part (often called the forcer) travels along a stationary magnetic track, producing smooth, fast, and precise motion without contact. The result is a cleaner, quieter, and more efficient system capable of submicron accuracy and rapid acceleration.

In essence, linear motion enables machines to move precisely and predictably, a necessity in fields like semiconductor manufacturing, automation, and inspection systems. It’s the invisible force driving innovation in modern engineering, and ITG Linear Motor continues to refine this technology to deliver exceptional performance for advanced industrial applications.

The Main Types of Linear Motion Systems

Linear motion systems come in several forms, each designed to achieve controlled, precise movement along a straight line. The choice of system often depends on application requirements such as speed, load capacity, precision, and environmental conditions.

Below are the primary types of linear motion systems used in modern engineering and automation.

1. Mechanical Linear Systems

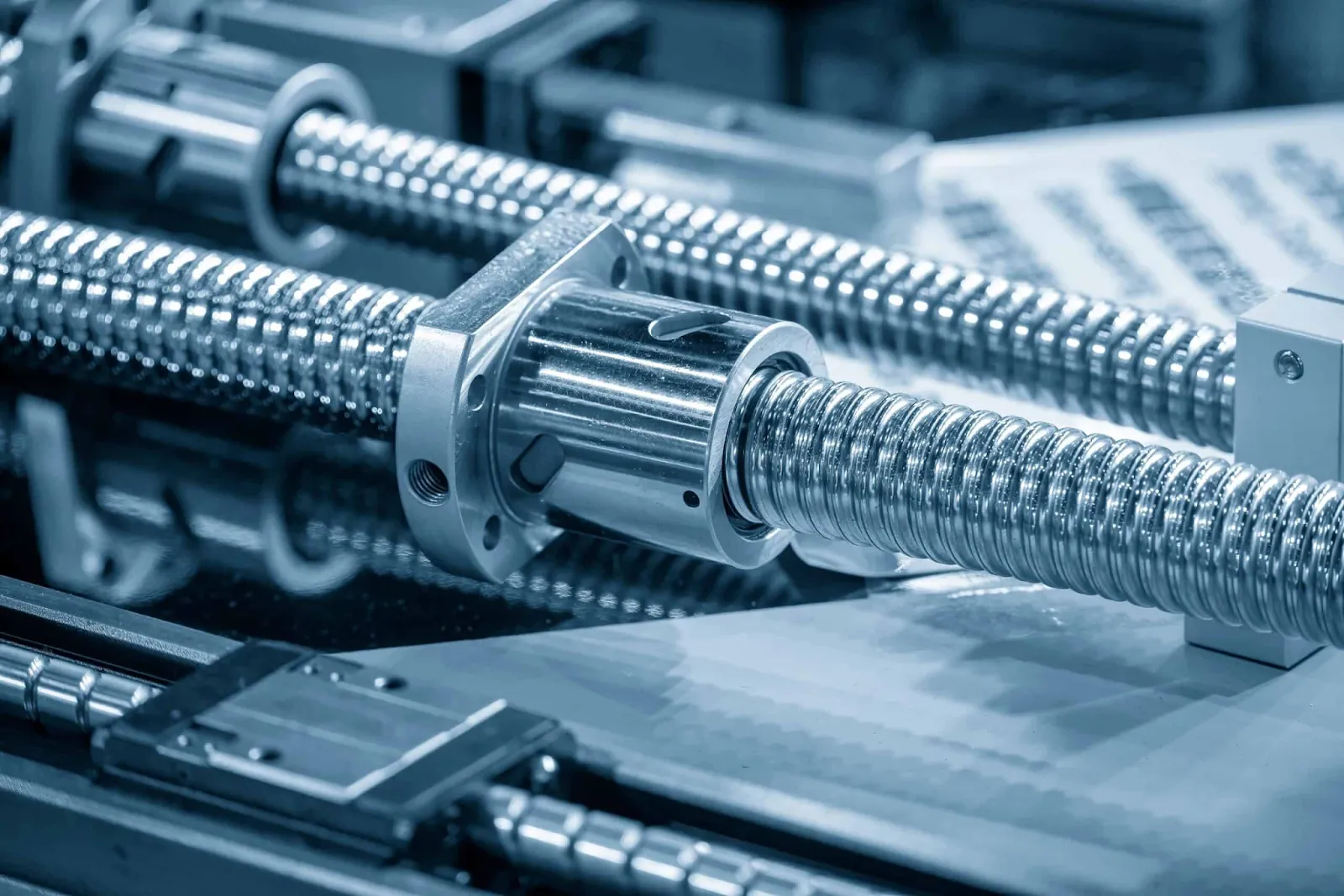

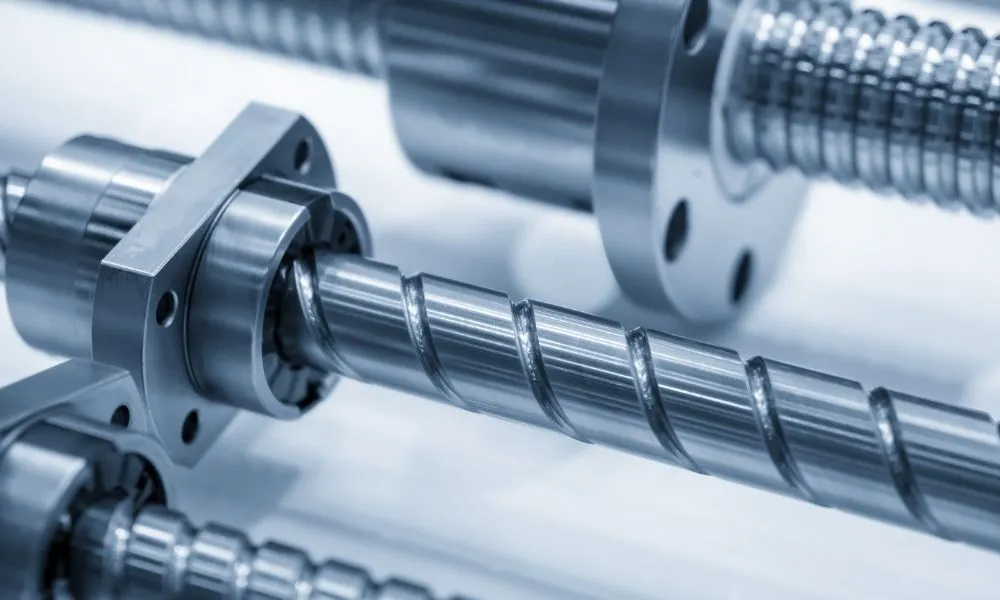

Mechanical linear systems are among the most common and time-tested solutions. They convert rotary motion from a motor into linear displacement using mechanisms such as lead screws, ball screws, or belt drives.

- Lead and ball screws use a threaded shaft to move a nut or carriage along the screw’s axis. Ball screws, in particular, reduce friction through ball bearings, providing smoother motion and higher efficiency.

- Belt-driven systems, on the other hand, use a continuous belt loop to transfer motion. They are ideal for long travel distances and high-speed applications but are generally less accurate than screw-based systems.

While mechanical systems are cost-effective and relatively simple to design, they suffer from drawbacks such as friction, wear, backlash, and vibration. These limitations make them less suitable for high-precision or high-speed environments where consistent accuracy is essential.

2. Linear Actuators

Linear actuators combine an electric motor with mechanical components (such as screws or belts) to produce controlled linear motion. They are compact, versatile, and easy to integrate into automation systems.

The Main Types of Linear Motion Systems

Applications include robotics, laboratory equipment, packaging, and medical devices, where precise positioning and repeatability are required. Depending on design, actuators can be electromechanical, hydraulic, or pneumatic, each offering different performance levels in terms of force, speed, and control complexity.

Despite their versatility, linear actuators still rely on mechanical transmission elements that can degrade over time. For systems that demand ultra-high precision or near-zero maintenance, an alternative approach is preferred: the linear motor.

3. Linear Motors

Linear motors represent the next generation of linear motion systems. Instead of converting rotary motion into linear displacement, they generate linear force directly through electromagnetic interaction. This direct-drive design eliminates all intermediate mechanical components, resulting in a frictionless, highly responsive motion profile.

A typical linear motor consists of a stator (or magnetic track) and a forcer (or moving coil). When current flows through the coils, electromagnetic forces propel the forcer along the stator’s length, achieving precise, high-speed motion with outstanding repeatability.

Because there are no mechanical transmissions, linear motors offer unmatched accuracy, acceleration, and reliability, making them the preferred choice in advanced industries such as semiconductor manufacturing, inspection systems, and precision automation.

Among the key innovators in this field, ITG Linear Motor provides a comprehensive range of high-performance linear motors engineered for superior motion control. Designed to deliver smooth, silent, and maintenance-free operation, ITG motors empower manufacturers to achieve greater productivity and precision in every application.

Principles Behind Linear Motion Systems

Every linear motion system, regardless of its design or technology, operates according to a set of fundamental physical principles. Understanding these principles helps engineers create motion solutions that balance speed, precision, stability, and energy efficiency, the four cornerstones of modern automation.

Principles Behind Linear Motion Systems

1. Force and Acceleration

Linear motion begins with Newton’s Second Law, force equals mass times acceleration (F = m × a). When a linear actuator or motor applies force to a load, that force determines how quickly the object accelerates.

In mechanical systems, part of this force is lost due to friction and inertia from transmission components like gears or screws. In contrast, linear motors generate direct electromagnetic force, which acts immediately on the moving element. This allows for instant acceleration, faster response times, and higher throughput in production systems.

2. Friction and Efficiency

Friction plays a critical role in determining system efficiency and longevity. Traditional motion systems rely on contact between moving parts, screws, bearings, and belts, all of which generate friction and wear over time.

Linear motors eliminate this issue by design. With no physical contact between the primary and secondary components, motion occurs magnetically rather than mechanically. This frictionless operation results in smoother movement, reduced maintenance, and a longer system lifespan, a major advantage in high-precision applications like semiconductor manufacturing or optical inspection.

3. Stiffness, Backlash, and Damping

For applications requiring nanometer-level precision, even minute mechanical imperfections can introduce errors.

- Stiffness ensures the system resists deformation under load, maintaining positioning accuracy.

- Backlash, the play or clearance between mechanical parts, causes lag in motion response.

- Damping helps control oscillations and vibrations during movement.

Because linear motors have no screws or belts, they inherently eliminate backlash and mechanical compliance. Combined with advanced feedback sensors and servo control systems, this design enables exceptional stiffness and stability, even under rapid acceleration or heavy loads.

4. Electromagnetic Principle of Linear Motors

At the heart of every linear motor lies the Lorentz force principle, the interaction between electric current and magnetic fields that produces motion. When a current passes through the motor’s coil within a magnetic field, it generates a force that propels the moving element along a straight path.

This direct-drive approach converts electrical energy straight into linear motion, without the need for intermediate mechanical conversion. The result is ultra-smooth, responsive, and precise control of position, velocity, and acceleration, a level of performance that conventional systems simply cannot match.

Applications of Linear Motion in Modern Industries

Linear motion systems are the unsung heroes behind many of today’s most advanced technologies. From manufacturing to healthcare, their ability to deliver smooth, fast, and precise movement enables innovations that define modern industry.

As the demand for automation, accuracy, and efficiency continues to grow, linear motion, especially through direct-drive linear motors has become indispensable across a wide range of sectors.

1. Semiconductor Manufacturing

In semiconductor fabrication, precision is everything. Processes such as wafer handling, photolithography, and inspection demand positioning accuracy down to the nanometer scale.

Linear motors play a crucial role here by offering frictionless, high-speed motion that ensures ultra-stable and repeatable movements.

ITG Linear Motor delivers the kind of fine motion control required to meet these extreme tolerances. With advanced magnetic design and optimized servo control, ITG motors enable semiconductor equipment to achieve submicron precision, reducing vibration and improving overall process yield.

2. Industrial Automation and Robotics

Automation systems rely on linear motion for everything from material handling to assembly lines and robotic positioning. The goal is to move quickly and accurately with minimal downtime or maintenance.

Linear motors provide direct and dynamic motion control, eliminating the mechanical complexity of traditional actuators. Robots powered by ITG Linear Motors benefit from higher acceleration, faster cycle times, and smoother trajectories, making them ideal for smart factories and high-speed production environments.

3. Medical and Laboratory Equipment

In the medical and life science sectors, precision and reliability are vital. Devices such as MRI scanners, DNA sequencers, and diagnostic analyzers all require quiet, accurate, and contamination-free motion.

Because linear motors operate without mechanical contact, they minimize particle generation and maintenance needs. ITG Linear Motor’s clean, efficient designs make them perfectly suited for sterile or sensitive environments, providing stable motion control that supports consistent, repeatable measurements in laboratory and medical applications.

4. Inspection and Measurement Systems

Inspection, metrology, and quality assurance systems depend on smooth, vibration-free movement to maintain high measurement accuracy. Linear motion ensures that sensors and cameras can scan products precisely and repeatably, a necessity for defect detection, surface analysis, and dimensional verification.

ITG Linear Motors enhance these systems by delivering ultra-smooth motion profiles and high responsiveness, resulting in faster scanning, better image resolution, and more reliable test results.

5. Precision Manufacturing and Machine Tools

In machining and precision manufacturing, linear motion enables controlled, high-speed cutting, engraving, or assembly with consistent quality. Linear motors are increasingly used in CNC machines, laser cutters, and 3D printers to achieve tight tolerances and superior surface finishes.

ITG Linear Motor technology provides the stiffness and dynamic control needed for such demanding environments, allowing manufacturers to push the limits of precision without compromising speed or durability.

Across every industry from semiconductors to automation, the advantages of direct-drive linear motion are clear: higher accuracy, less maintenance, and greater efficiency. ITG Linear Motor continues to drive this evolution by delivering innovative, reliable solutions that empower engineers to design faster, smarter, and more precise systems for the future of manufacturing and beyond.

Conclusion

Linear motion is more than just a mechanical concept, it is the invisible force that powers modern innovation. From the silent precision of semiconductor equipment to the high-speed choreography of industrial robots, linear motion defines how machines move, build, and create with unmatched accuracy.

As industries evolve toward smarter, faster, and cleaner production, linear motors have become the heart of next-generation automation delivering direct, frictionless, and highly responsive performance.

Readmore Blog ITG:

what is linear motion

linear motion drives

high precision linear motor

high torque servo motors

linear motor controller

linear motor technology

servo motor linear

high torque electric motors