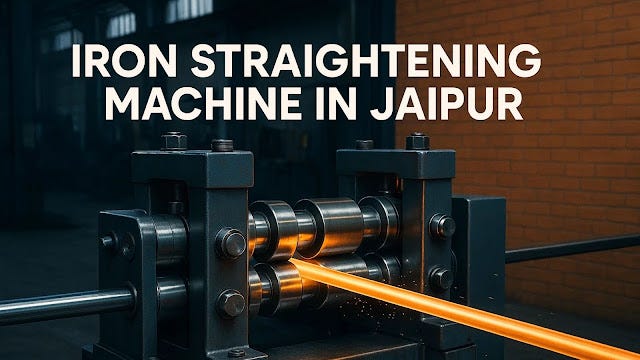

How to Choose the Right Iron Straightening Machine in Jaipur

This blog is about How to Choose the Right Iron Straightening Machine in Jaipur

Selecting the right Iron Straightening Machine in Jaipur is a crucial decision for fabricators, construction units, infrastructure developers, and metal processing industries. A high-quality straightening machine not only enhances productivity but also ensures precise shaping of channels, angles, beams, flats, and other structural sections. With growing industrial demand, Jaipur has become a major hub for powerful and reliable iron straightening solutions. But how do you choose the perfect machine for your requirements? This detailed guide will help you evaluate key factors, compare industry leaders, and understand essential features before making a purchase.

1. Understand Your Material Requirements

Before selecting any straightening system, identify the type and size of material you handle regularly. Whether you work with angles, channels, beams, or flats, your machine must match your operational needs.

For example, industries that work primarily with angles often prefer the Angle Straightening Machine, which offers superior accuracy while shaping angle sections. Many companies across the country rely on an Angle Section Straightening Machine in India due to its durability and stable performance.

2. Choose a Trusted Manufacturer or Supplier

The credibility of the manufacturer significantly influences the quality, performance, and lifespan of your straightening machine. When choosing a machine, always consider companies with expertise in section straightening technology.

Top manufacturers in India include:

- Section Straightening Manufacturer in India

- Channel Straightening Machines Manufacturer in India

- Section Straightening Machine Supplier in India

- Section Straightening Machine Exporter in India

These manufacturers focus on producing robust machines designed for long-term use. Jaipur fabricators should ideally shortlist companies known for delivering high-precision straightening solutions with strong after-sales support.

3. Evaluate Technical Specifications

To choose the right Iron Straightening Machine in Jaipur, carefully review the technical features such as:

- Roller size and material

- Straightening capacity

- Hydraulic or mechanical operation

- Motor power and load handling

- Straightening speed

- Automation options

Machines such as the Section Straightening Machine Supplier in India offer multiple models to meet different load capacities and metal types. This allows industries to pick machines that match exact project requirements.

4. Compare Angle Straightening Machine Price in India

Budget is a major factor when buying industrial machinery. Before making a decision, always compare the Angle Straightening Machine Price in India offered by top manufacturers. Keep in mind:

- Higher price often indicates better steel quality, durability, and precision.

- Some suppliers offer semi-automatic models at affordable rates.

- Export-quality machines from a Section Straightening Machine Exporter in India might have additional features.

To get the best value, avoid going for the cheapest option. Instead, choose a machine with the right balance of performance, durability, and cost.

5. Look for After-Sales Support and Spare Availability

Reliable after-sales support ensures smooth machine functioning and reduces downtime. Companies like Channel Straightening Machines Manufacturer in India and other reputed suppliers often provide:

- On-site installation

- Maintenance services

- Spare parts availability

- Technical assistance

Before investing in a straightening machine, verify that the supplier provides timely service in Jaipur and nearby industrial zones.

6. Consider Export-Quality Machines for Better Performance

If you aim for long-term benefits and heavy-duty performance, consider machines from a reputed Section Straightening Machine Exporter in India. Export-quality machines usually come with:

- High-precision rollers

- Automated control systems

- Better structural body

- Enhanced straightening accuracy

Buying export-quality machines ensures productivity and accuracy even for large-scale fabrication units.

7. Check Compatibility With Other Industrial Equipment

Many industries in Jaipur also use cranes and heavy lifting equipment along with straightening machines. If your workshop already has lifting systems like:

- Single Girder EOT Crane Manufacturer in India

- EOT Crane Supplier

- Single Girder EOT Cranes

- EOT Crane Exporter in India

- Gantry Cranes Manufacturers in India

- Gantry Cranes Suppliers in India

…then your straightening machine must be compatible with your existing setup. For example, straightening machines with overhead loading can easily integrate with Single Girder EOT Cranes, making the material handling process much smoother.

8. Review Customer Feedback and Market Reputation

Customer testimonials are powerful indicators of machine performance. Search for reviews from industries that have purchased from leading Section Straightening Manufacturer in India. Positive feedback shows:

- Smooth machine functioning

- High straightening accuracy

- Low maintenance costs

- Strong customer support

When buying in Jaipur, choose manufacturers with consistently good feedback for reliability and performance.

9. Opt for Energy-Efficient and Low-Maintenance Models

A straightening machine is a long-term investment. Always choose a model that is energy-efficient and requires minimal maintenance. New-generation machines designed by Channel Straightening Machines Manufacturer in India are built to reduce power consumption while improving output. Features such as automated lubrication systems and hardened rollers also extend the machine’s lifespan.

10. Final Checklist Before Buying an Iron Straightening Machine in Jaipur

Here is a final checklist that will help you make the right decision:

✔ Identify your material type (angles, channels, beams, flats). ✔ Check machine capacity and roller specifications. ✔ Compare Angle Straightening Machine Price in India. ✔ Check support from a reputed Section Straightening Machine Supplier in India. ✔ Verify after-sales service and spare availability. ✔ Ensure compatibility with existing lifting equipment like EOT Cranes or Gantry Cranes. ✔ Choose export-quality if long-term heavy usage is needed. ✔ Prefer trusted manufacturers with proven industry reputation.

Conclusion

Choosing the right Iron Straightening Machine in Jaipur becomes easy when you understand your industrial requirements and work with reliable manufacturers. Whether you need an Angle Section Straightening Machine in India, a high-capacity channel straightening system, or a complete workshop setup with EOT Cranes and Gantry Cranes, always prioritize durability, accuracy, workflow compatibility, and professional support.

With the right machine, fabricators in Jaipur can significantly enhance production speed, improve precision, reduce labor costs, and meet growing market demands efficiently.