Green and Bio Polyols Market: Driving the Sustainable Revolution in Polyurethane Production

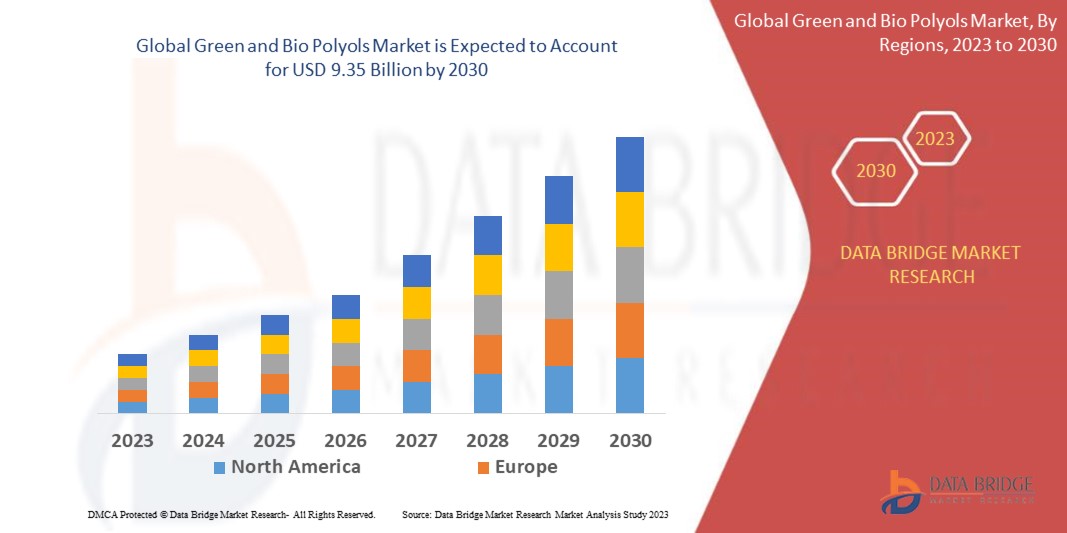

Global green and bio polyols market is expected to reach USD 1,483.90 million by 2032 from USD 875.43 million in 2024, growing with a substantial CAGR of 6.9% in the forecast period of 2025 to 2032.

Global Green and Bio Polyols Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2032

https://www.databridgemarketresearch.com/reports/global-green-bio-polyols-market

Global green and bio polyols market is expected to reach USD 1,483.90 million by 2032 from USD 875.43 million in 2024, growing with a substantial CAGR of 6.9% in the forecast period of 2025 to 2032.

The Green and Bio Polyols Market is gaining substantial momentum as industries worldwide transition toward sustainable and eco-friendly alternatives to petroleum-based chemicals. Derived from renewable resources such as natural oils, plant-based materials, and recycled feedstock, green and bio polyols are transforming the way polyurethanes are produced, offering both environmental and economic advantages. With the growing emphasis on carbon neutrality, energy efficiency, and sustainable manufacturing, this market is poised to reshape the global chemical landscape.

The Green and Bio Polyols Market is gaining substantial momentum as industries worldwide transition toward sustainable and eco-friendly alternatives to petroleum-based chemicals. Derived from renewable resources such as natural oils, plant-based materials, and recycled feedstock, green and bio polyols are transforming the way polyurethanes are produced, offering both environmental and economic advantages. With the growing emphasis on carbon neutrality, energy efficiency, and sustainable manufacturing, this market is poised to reshape the global chemical landscape.

Understanding Green and Bio Polyols

Polyols are key building blocks used in producing polyurethanes, which are widely applied in foams, coatings, adhesives, sealants, and elastomers. Traditionally, these polyols are derived from petrochemical sources. However, green and bio polyols are produced from renewable feedstocks such as soybean oil, castor oil, palm oil, canola oil, and even recycled polyethylene terephthalate (PET). This shift not only reduces dependency on fossil fuels but also lowers greenhouse gas emissions, making the process more sustainable and circular.

Green polyols refer to polyols created using carbon dioxide or other non-petroleum resources, while bio polyols are derived specifically from natural biomass. Together, they form the cornerstone of eco-friendly polyurethane materials, enabling manufacturers to align with global environmental goals and regulatory frameworks aimed at reducing the carbon footprint.

Market Drivers Accelerating Growth

Sustainability and Regulatory Push: Governments and environmental organizations across the globe are enforcing strict regulations to minimize carbon emissions and promote the use of green chemicals. Initiatives like the Paris Agreement and regional carbon neutrality targets are motivating companies to invest in bio-based alternatives.

Rising Demand from the Construction and Automotive Sectors: Polyurethanes made from bio polyols are extensively used in insulation panels, sealants, and flexible foams. In the automotive industry, manufacturers are adopting bio-based materials for seat cushions, interior panels, and coatings to enhance recyclability and reduce vehicle weight.

Consumer Preference for Eco-friendly Products: The growing awareness of sustainable consumption has shifted consumer preferences toward green materials. Companies that integrate bio-based components in their products are gaining a competitive advantage by aligning with customer expectations and sustainability certifications.

Technological Advancements in Bio-based Feedstock: Innovations in feedstock processing and catalytic conversion technologies are improving yield efficiency and product quality. The ability to create bio polyols with performance characteristics comparable to petrochemical counterparts is fueling large-scale adoption across various industries.

Market Challenges and Constraints

Despite the strong growth potential, the green and bio polyols market faces a few challenges:

High Production Costs: Bio-based raw materials and manufacturing processes can be more expensive than traditional methods, affecting the overall cost structure and profit margins.

Feedstock Availability and Supply Chain Issues: Dependence on agricultural outputs such as soy or palm oil makes the supply chain susceptible to fluctuations caused by seasonal changes or geopolitical disruptions.

Limited Awareness in Emerging Markets: While developed economies have made significant progress toward green manufacturing, several developing regions still rely on conventional materials due to cost and infrastructure limitations.

Overcoming these challenges requires strategic collaborations between manufacturers, technology providers, and government bodies to create sustainable ecosystems that support production and affordability.

Applications Across Industries

The versatility of green and bio polyols allows their use in multiple industries, each reaping benefits from their eco-friendly nature:

Building and Construction: Bio polyols are used to produce rigid polyurethane foams for insulation panels, roofing, and structural boards. Their excellent thermal properties enhance energy efficiency, aligning with green building standards.

Automotive: Lightweight bio-based foams and coatings help reduce vehicle emissions and improve fuel efficiency. Automotive manufacturers are incorporating bio polyols in seat cushions, dashboards, and interior trims.

Furniture and Bedding: Flexible foams derived from bio polyols are being used in mattresses, cushions, and upholstery, offering comfort and sustainability simultaneously.

Adhesives, Sealants, and Coatings: Green polyols provide strong adhesion and superior durability, making them suitable for eco-friendly paints, coatings, and adhesives used across industrial and consumer products.

Packaging and Consumer Goods: Bio-based polyurethane films and packaging materials are gaining traction in the consumer goods sector as brands shift toward biodegradable and recyclable packaging solutions.

Regional Insights

North America leads the market due to strong governmental support for renewable materials and the presence of major polyurethane manufacturers adopting bio-based feedstocks.

Europe is another prominent region, driven by strict environmental laws and sustainability commitments from the European Union.

Asia-Pacific is witnessing rapid growth due to increasing industrialization, expansion of the automotive and construction sectors, and rising awareness of sustainable alternatives. Countries like China, India, and Japan are investing heavily in renewable chemical technologies.

Latin America and the Middle East & Africa are gradually entering the market as industrial and environmental reforms take shape, creating opportunities for new entrants and investors.

Future Outlook: Toward a Circular Economy

The future of the Green and Bio Polyols Market looks promising, with ongoing R&D focusing on enhancing product performance, reducing costs, and improving feedstock availability. The integration of CO₂-based polyols, which utilize captured carbon dioxide as a raw material, represents a major breakthrough toward carbon recycling and utilization.

Moreover, as circular economy models become mainstream, industries will increasingly rely on bio-based inputs to minimize waste and maximize resource efficiency. Companies that invest early in green chemistry innovations and sustainable production systems are likely to benefit from regulatory incentives, brand value enhancement, and long-term cost savings.

Conclusion

The global shift toward sustainability is no longer optional—it’s an imperative. The Green and Bio Polyols Market exemplifies how innovation and environmental responsibility can coexist to create high-performance materials without compromising the planet’s future. From renewable feedstocks to carbon-neutral production processes, this market is driving a transformative wave in the polyurethane industry.

Browse More Reports :

Europe Cosmetics Market Global Furniture Fittings Market Global Metal Roofing Market West Africa Baby Food Market Global Adult Diapers Market Global Aesthetic Dermatology Market Global Caviar Market Global Coffee Machines Market Global Dairy Market Global Endometriosis Market Global Ethylbenzene Market Global Green and Bio Polyols Market Global Gummies and Jellies Market Global Industrial Oxygen Market