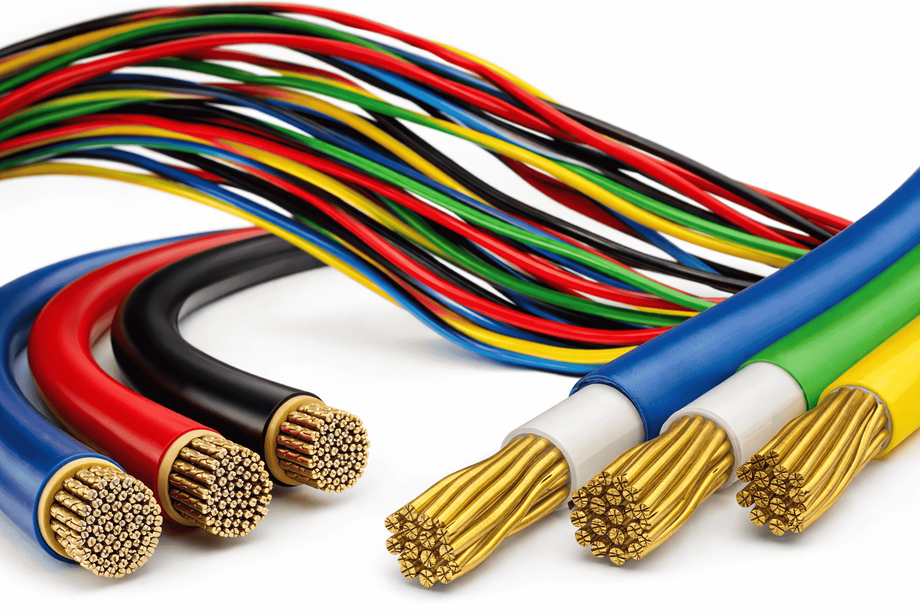

Conductor Braids for Power Plants, Substations, and Industrial Systems

Electrical failures in high-load systems often start at rigid connection points, not major equipment. Conductor braids cable designs add flexibility, reduce heat and vibration stress,

In large power plants and industrial facilities, most attention goes to big equipment. Transformers, generators, panels, and switchgear usually take center stage. Yet, many electrical failures do not begin there. They start quietly at the connection points.

As power systems carry higher loads and operate for longer hours, stress builds up at joints and terminals. Heat rises. Vibration increases. Materials go through expansion and contraction every day. By 2026, these conditions will no longer be exceptions. They will be the norm.

This is why conductor braids cable designs matter more than ever. They may look simple, but they play a decisive role in keeping systems stable. Understanding how they work helps engineers and buyers choose wire solutions that are reliable, safe, and have a long service life.

The Hidden Role of Flexible Conductors in High-Load Systems

Why rigid connections struggle over time

Traditional rigid connections are strong, but they are not forgiving. When electrical systems heat up, metals expand. When they cool, metals contract. Add to that the vibration from heavy machinery or generators, and stress starts to build at fixed joints. Over time, this stress weakens contact points.

This is where conductor braids cable designs offer a clear advantage. Their flexible structure allows movement without breaking electrical continuity. Instead of forcing stress into terminals, braided conductors absorb it naturally. These factors make them an essential part of modern wire solutions, especially in high-load environments.

What industry experience consistently shows

Maintenance teams across power plants and substations often notice and report the same pattern again and again. When systems use stiff, rigid connections at important joints, those joints loosen over time. Teams have to keep tightening them and checking for problems. Heat marks also appear more often at these points.

When braided conductors are used instead, these issues are reduced. The connections stay firm, and there is less heat buildup.

This difference becomes very clear during peak load times, when power demand is high. Flexible conductors stay in contact even when temperatures rise or equipment moves. Because of this, systems run more smoothly, emergency shutdowns happen less often, and maintenance becomes more planned instead of sudden.

Where this matters today

Flexible braided conductors are now commonly seen in generator terminals, transformer connections, busbar joints, and earthing systems. In each case, the goal is the same. Keep power flowing without stressing the connection.

Thermal Stability and Electrical Performance Under Load

Heat buildup starts at weak points

Heat is one of the biggest enemies of electrical systems. Even when cables are correctly sized, poor connections can create resistance. Resistance creates heat. Heat weakens insulation and contact surfaces.

A conductor braids cable helps manage this risk. Its larger surface area allows heat to spread and dissipate more evenly. Current flows smoothly instead of concentrating at a single rigid point. As part of reliable wire solutions, braided conductors help keep temperatures under control.

What operating data reveals

In factories and power plants, machines often run all day without stopping. When this happens, some connection points get hotter than others. Data shows that stiff, solid connections usually become very hot, especially after they have been used for many years.

Braided conductors behave differently. They spread the heat more evenly, so their temperature stays more stable over time.

This is important because too much heat makes parts wear out faster. When heat stays lower, nearby parts last longer. It also helps save energy, because less electricity is wasted as heat.

Practical applications

Braided conductors are used in places where a lot of electricity flows, like busbars, transformer connections, and switchgear. These areas often do not have much airflow, so heat cannot escape easily.

Using braided conductors in these spots helps keep temperatures under control and keeps the system running safely for a longer time.

Vibration, Movement, and Mechanical Stress

Movement is part of industrial reality

In power plants and factories, machines are always moving. Generators keep spinning. Motors turn on and off. Heavy equipment creates constant vibration. Trying to eliminate movement completely is unrealistic.

A conductor braids cable is designed to handle this movement. It bends and adjusts as machines run, instead of staying stiff. Because it can move, it does not crack, break, or come loose the way rigid conductors often do. This is why braided conductors are reliable wire solutions that protect both the electricity flow and the physical connection.

What failure reviews highlight

When engineers study why electrical systems fail, they often find the same reason. Small movements repeat again and again over time. These tiny movements slowly weaken stiff connections.

Once a connection weakens, electricity does not flow smoothly. This causes heat and sometimes sparks.

Places that replace rigid connections with braided conductors at high vibration points see fewer problems. Even when machines keep moving, the connections stay firm and safe.

Common use cases

Braided conductors are used in many busy parts of electrical systems. You will find them at generator outputs, motor connections, busbar joints, and grounding straps near shaking machines.

In all these places, flexibility helps the system stay reliable and work without interruptions.

Safety, Grounding, and Compliance

Grounding depends on consistent contact

A grounding system is only as strong as its weakest connection. If a ground path breaks or loosens, fault currents may not flow safely to earth. This increases the risk to equipment and personnel.

A conductor braids cable provides reliable grounding even under heat and vibration. Its flexibility ensures continuous contact with grounding points. As part of safety-focused wire solutions, braided grounding conductors play a critical role in protection systems.

How standards view connection quality

Modern electrical safety standards emphasize not just on the thickness and strength of the conductor, but also on connection reliability. Inspectors look for secure, stable grounding paths that will perform during faults. Braided conductors help meet these expectations by maintaining low resistance paths over time.

Where braided grounding is used

Substations, control panels, industrial enclosures, and power plants often use braided grounding straps to connect doors, frames, and equipment to earth. These connections must remain effective for years without constant adjustment.

Designing for Longevity in Industrial Electrical Systems

Planning beyond installation day

Installing an electrical system is only the beginning. The real test is how it performs after years of heat cycles, vibration, and load changes. Short-term savings from rigid links can lead to long-term costs in maintenance and downtime.

Choosing conductor braids cable designs early supports long-term stability. As part of thoughtful wire solutions, braided conductors reduce stress on terminals and extend system life.

How design thinking is evolving

Engineers and buying teams now think beyond just the initial cost. They focus on how long a system will last and how easy it is to maintain. They consider how often connections need checking, how expensive downtime can be, and what happens if a failure occurs.

Braided conductors perform well in all these areas because they stay stable and need less attention over time.

Systems that benefit the most

Power plants, substations, renewable energy sites, and heavy factories benefit the most from braided conductors. These places run their electrical systems almost all the time and cannot stop work often for repairs or inspections.

Practical Takeaways for Engineers and Buyers

- Use conductor braids cable options where heat and vibration are unavoidable

- Review connection points as carefully as cable ratings

- Select flexible wire solutions for busbars and grounding paths

- Design electrical systems for long-term performance, not just initial setup

- Reduce maintenance risk by allowing connections to absorb movement naturally

Looking Ahead at Industrial Electrical Reliability

Electrical systems rarely fail without warning. Problems often begin at small points that are easy to overlook. Connection quality determines how well power flows, how heat is managed, and how safely faults are handled.

As industrial demand grows and systems become more compact, these factors will only become more important. Conductor braids cable designs are no longer optional additions. They are foundational elements of dependable wire solutions.

The future of power infrastructure will favor systems built for flexibility, stability, and long service life. The real question is whether today’s connection choices are ready to meet tomorrow’s operating demands.