Automatic Dual Spindle Glass Drill Machine | Ervin Sales Group USA

One of the most advanced solutions available is the Automatic Dual Spindle Glass Drill Machine offered by Ervin Sales Group USA. Designed

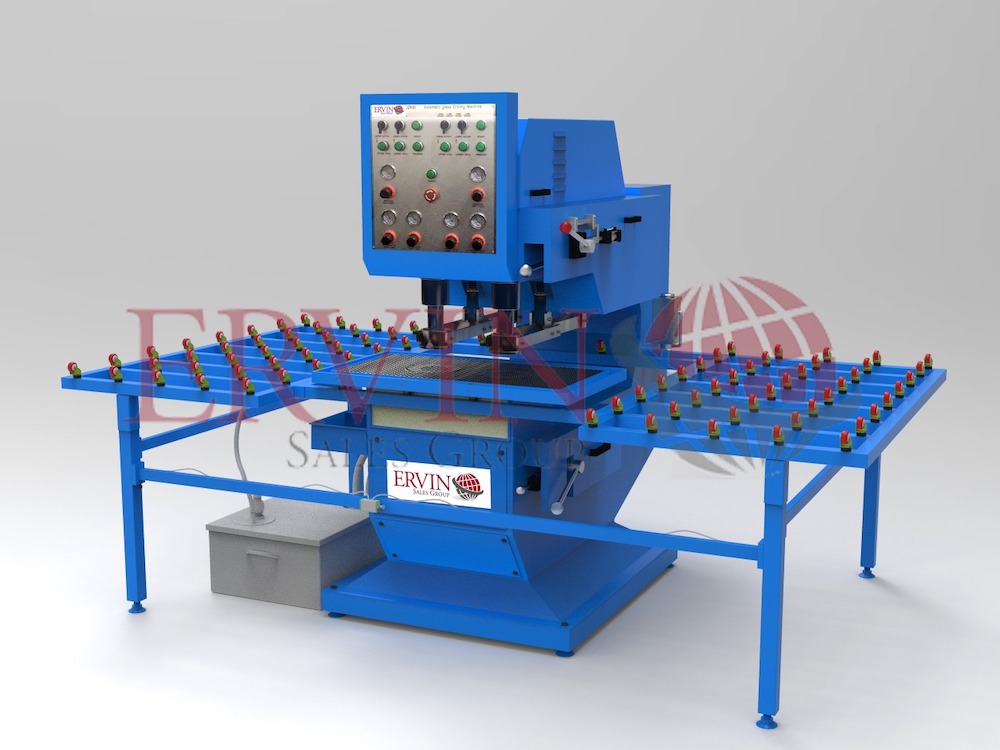

In today’s competitive glass manufacturing industry, precision, speed, and efficiency are essential. One of the most advanced solutions available is the Automatic Dual Spindle Glass Drill Machine offered by Ervin Sales Group USA. Designed for high-performance glass processing, this machine helps businesses achieve superior drilling accuracy while maximizing productivity.

Whether you operate in architectural glass, furniture manufacturing, or custom glass fabrication, investing in modern glass machinery is key to staying ahead in the market.

What Is an Automatic Dual Spindle Glass Drill Machine?

An Automatic Dual Spindle Glass Drill Machine is a specialized piece of equipment used to drill precise holes in glass panels. It features two synchronized spindles that work simultaneously from both sides of the glass, ensuring perfect alignment and minimizing breakage.

This advanced glass drilling machine is ideal for producing holes for hinges, handles, fittings, and mounting systems in various glass products.

Key Features and Benefits

1. Dual Spindle Technology

The dual spindle design allows drilling from both sides at the same time, ensuring smooth and accurate holes without chipping or cracking.

2. High Precision and Consistency

With automated controls and advanced positioning systems, this machine delivers consistent results across large production volumes.

3. Increased Productivity

By drilling multiple holes quickly and accurately, manufacturers can significantly reduce processing time and labor costs.

4. Durable Construction

Built with high-quality components, the machine is designed for long-term industrial use with minimal maintenance.

5. Integration with Glass Processing Lines

The machine can be integrated with other equipment such as a glass cutting machine and glass washing machine, creating a streamlined production workflow.

Why Choose Ervin Sales Group USA?

Ervin Sales Group USA is a trusted supplier of premium glass machinery solutions. Their Automatic Dual Spindle Glass Drill Machine is engineered to meet the highest industry standards, offering reliability, performance, and excellent customer support.

When you choose Ervin Sales Group USA, you benefit from:

- Industry expertise

- Proven machine quality

- Professional technical support

- Competitive pricing

- Customized solutions

Applications of the Automatic Dual Spindle Glass Drill Machine

This advanced machine is widely used in:

- Architectural and structural glass fabrication

- Shower doors and partitions

- Furniture and tabletop manufacturing

- Automotive glass processing

- Commercial glazing projects

It works seamlessly with other equipment such as glass cutting machines and glass washing machines, making it an essential part of a modern glass production line.

Enhancing Efficiency with Complete Glass Machinery Solutions

For maximum efficiency, many manufacturers combine the Automatic Dual Spindle Glass Drill Machine with:

- Glass Cutting Machine – for accurate shaping and sizing

- Glass Washing Machine – for removing dust and residues

- Glass Drilling Machine – for precise hole processing

- Other automated glass machinery

This integrated approach reduces waste, improves quality, and speeds up production.

Frequently Asked Questions (FAQs)

1. What is the main advantage of an Automatic Dual Spindle Glass Drill Machine?

The main advantage is its ability to drill from both sides simultaneously, ensuring perfect alignment, reduced breakage, and faster processing.

2. Can this machine handle different glass thicknesses?

Yes, most models are designed to work with a wide range of glass thicknesses, making them suitable for various applications.

3. Is operator training required?

Basic training is recommended. However, the machine is user-friendly and equipped with automated controls for easy operation.

4. Can it be integrated with other glass machinery?

Absolutely. It works well with glass cutting machines, glass washing machines, and other production-line equipment.

5. How often does the machine require maintenance?

With proper use and regular inspections, maintenance requirements are minimal. Routine cleaning and lubrication are usually sufficient.

Why Invest in an Automatic Dual Spindle Glass Drill Machine?

Investing in an Automatic Dual Spindle Glass Drill Machine is a smart decision for businesses that want to:

- Improve product quality

- Increase production speed

- Reduce material waste

- Lower labor costs

- Stay competitive in the glass industry

With growing demand for precision glass products, modern equipment is no longer optional—it’s essential.

Call to Action

Ready to upgrade your glass processing capabilities?

📞 Contact Ervin Sales Group USA today to learn more about the Automatic Dual Spindle Glass Drill Machine and discover the perfect solution for your business.

Visit: https://www.ervinsales.com/glass-machinery-products/automatic-dual-spindle-glass-drill-machine.html

Contact:

ERVIN, Inc. 13116 Lincoln Way #3138 Auburn, CA 95604 Ph: 9169338367 Email: sales@ervinsales.com