5 Reasons a Vertical Centrifugal Pump Is the Best Choice for US Industrial Applications

Discover why vertical centrifugal pumps are vital for US industries. Learn about use cases, advantages, technical specs, and how ATO Automation supports efficient operations.

Why Vertical Centrifugal Pumps Are Gaining Momentum

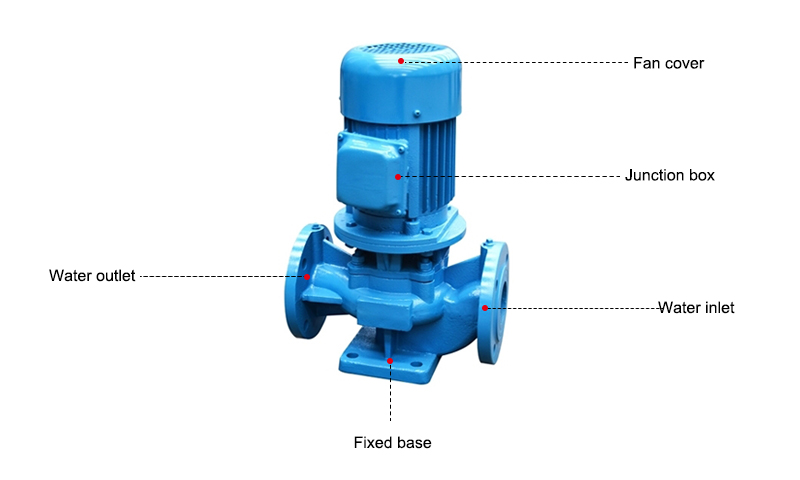

In American industries where efficiency and reliability are non-negotiable, choosing the right pumping system can directly impact performance and costs. The vertical centrifugal pump has emerged as one of the most effective solutions for fluid handling in manufacturing, HVAC, municipal water supply, and fire protection systems. Its vertical inline design, where inlet and outlet are aligned on the same centerline, makes it compact and easy to integrate into existing pipelines. For many US engineers and plant managers, this pump design is not only about moving liquid but also about saving space, reducing downtime, and meeting modern efficiency expectations.

Common Applications and Use Cases

Vertical centrifugal pumps are widely adopted across industries because of their versatility. In commercial buildings and data centers, they are a cornerstone of HVAC systems, ensuring chilled water circulation and air conditioning reliability. Municipalities use them for urban water supply and fire suppression, while factories deploy them for pipeline pressurization in production lines. Their ability to handle steady flows of water or other clean fluids makes them the preferred choice for irrigation projects, boiler feed systems, and large-scale cooling towers. Unlike horizontal pumps that take up more space, vertical designs fit neatly into limited floor areas, making them ideal for crowded mechanical rooms.

What Buyers in the US Market Are Looking For

When American buyers search for a vertical centrifugal pump, they rarely focus only on the price tag. Instead, they want clarity on performance and longevity. Engineers often cite concerns about noise and vibration, or difficulty in replacing seals and bearings. Others point to high energy bills when older models consume more power than necessary. These pain points highlight the unmet demand for pumps that combine durability with efficiency. ATO Automation, for example, provides models with mounting feet for extra stability and offers flexibility in outlet positions—0°, 90°, or 180°—to simplify integration into existing systems. This addresses the very issues buyers face during installation and operation.

Advantages of the Vertical Centrifugal Pump

Several features make vertical centrifugal pumps stand out:

- Compact footprint: Their inline structure allows installation directly into pipelines, like a valve, without taking up additional space.

- Stable operation: Mounting feet increase pump stability, reducing vibration and noise during continuous use.

- Flexibility: With selectable outlet angles, engineers can adapt the pump to different layouts, lowering installation complexity.

- High capacity range: ATO offers three-phase vertical centrifugal pumps ranging from 1 hp to 100 hp, making them suitable for small commercial systems up to heavy-duty industrial applications.

- Versatility: Equally effective in industrial and urban applications, from fire water systems to production line pressurization.

These strengths make the pump especially appealing to facilities in the US that need reliable, around-the-clock performance while maximizing floor space.

Technical Highlights That Matter to Engineers

For decision-makers, numbers often speak louder than promises. ATO’s vertical centrifugal pump models are designed with practical specifications: inlet and outlet diameters from 25mm (1 inch) to 85mm (3 inch), ensuring compatibility with a wide range of piping systems. The single-stage impeller design makes maintenance simpler while maintaining efficiency for continuous duty. As a non-self-priming centrifugal pump, it is best suited for applications where the system can ensure adequate fluid supply to the pump inlet. By highlighting these technical details, suppliers reassure engineers that the equipment will deliver as expected in demanding environments.

Meeting Unmet Needs in Industrial Pumping

Despite their benefits, the US market still shows gaps in meeting all buyer expectations. Some smaller companies struggle with maintenance expertise, wishing pumps were easier to service. Others seek more energy-efficient models to comply with sustainability goals. Still others want transparent guidance on selecting the correct horsepower and impeller size for their specific application. By addressing these gaps with resources, detailed documentation, and responsive customer support, suppliers like ATO Automation stand out as trusted partners rather than just equipment providers.

Why Vertical Centrifugal Pumps Are the Smart Choice

Choosing a vertical centrifugal pump is ultimately about securing long-term reliability. Downtime from pump failure can halt entire production lines or compromise safety systems like fire suppression. With options ranging from 1 hp to 100 hp, selectable outlet positions, and durable construction materials, today’s pumps are more adaptable than ever. For US buyers balancing compliance, efficiency, and budget, the vertical centrifugal pump represents a solution that bridges practicality with innovation.

About Us

With over 20 years of experience in industrial automation and fluid handling, we have partnered with manufacturers, utilities, and engineering firms worldwide. Headquartered in the United States, ATO Automation provides vertical centrifugal pumps and related solutions that align with the needs of American industries. Our collaborations and expertise ensure that every pump we deliver not only meets specifications but also helps businesses achieve long-term operational success.