3D Printing Market 2033: Desktop vs. Industrial Printers—The Great Debate

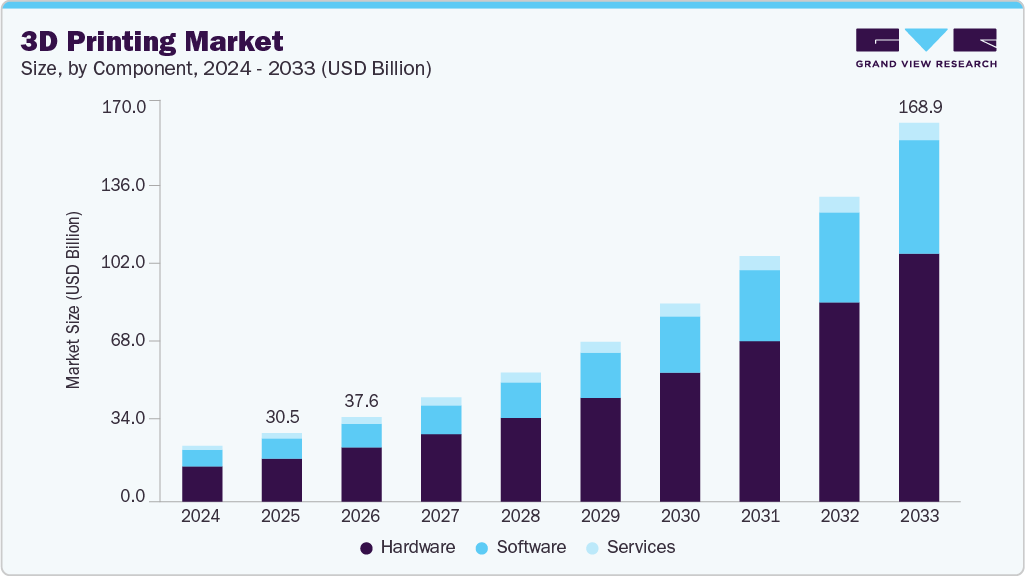

The global 3D printing market was valued at USD 30.55 billion in 2025 and is projected to reach USD 168.93 billion by 2033.

The global 3D printing market was valued at USD 30.55 billion in 2025 and is projected to reach USD 168.93 billion by 2033, with a CAGR of 23.9% from 2026 to 2033. This growth is largely driven by aggressive research and development (R&D) in three-dimensional printing and increasing demand for prototyping across key industries such as healthcare, automotive, and aerospace & defense.

A key factor fueling the growth of the market is the rising demand for customized products in sectors like healthcare, automotive, aerospace, and consumer goods. 3D printing allows for the production of highly customized products without the time and cost constraints typically associated with traditional manufacturing. This shift toward tailored production is encouraging businesses to adopt additive manufacturing (AM) as a central element of their production strategy.

In addition to the demand for customization, advancements in 3D printing technologies are pushing the market forward. Improvements in hardware, software, and printing materials are enhancing the efficiency and capabilities of 3D printers. Innovations such as multi-material printing, metal additive manufacturing, faster print speeds, and higher precision systems are expanding the applications of 3D printing. Furthermore, the development of advanced materials, including high-performance thermoplastics, biocompatible resins, and lightweight metals, is enabling 3D printing in industries that require specialized attributes such as durability and medical compatibility.

Industries are also integrating 3D printing into their production workflows for rapid prototyping, tooling, and mass customization. Key sectors, including aerospace, automotive, and industrial machinery, are leveraging additive manufacturing to shorten development cycles, enhance design flexibility, and reduce costs compared to conventional manufacturing methods. The ability to produce complex geometries and lightweight structures gives companies a competitive edge, driving wider adoption of 3D printing in industrial applications.

Order a free sample PDF of the 3D Printing Market Intelligence Study, published by Grand View Research.

Key Market Trends & Insights

- Regional Leadership: North America dominated the 3D printing market in 2025, holding a 32.8% share, due to early adoption of additive manufacturing technologies in countries such as the U.S. and Canada.

- Component Trends: The hardware segment led the market in 2025, capturing 62.6% of the share. The growing demand for rapid prototyping and advanced manufacturing processes, coupled with industrialization and rising consumer electronics usage, is fueling hardware growth.

- Technology Trends: The stereolithography segment was the dominant technology in 2025. Although it remains one of the oldest and most reliable 3D printing methods, ongoing R&D efforts are creating new opportunities for more efficient and advanced technologies.

- Software Trends: Design software led the market in 2025, and it is expected to continue to dominate during the forecast period. Design software plays a crucial role in industries like automotive, aerospace, and engineering by providing the necessary interface for designing objects to be printed.

- Application Trends: Prototyping is the fastest-growing application in the 3D printing market, with significant adoption across industries like automotive, aerospace, and defense. Prototyping allows for the design and development of parts and systems with high precision and reliability, making it a key driver for the market.

- Material Trends: Metals dominated the 3D printing materials market in 2025. Strong growth is seen in the adoption of metal additive manufacturing for high-performance and end-use applications, with metals like titanium, stainless steel, aluminum, and nickel alloys being widely used in sectors like aerospace, automotive, and healthcare.

- Printer Type Trends: Industrial printers held the largest market share in 2025, driven by their extensive use in heavy industries such as aerospace, automotive, and healthcare. Industrial printers are commonly used for prototyping, tooling, and designing across these sectors.

Market Size & Forecast

- 2025 Market Size: USD 30.55 Billion

- 2033 Projected Market Size: USD 168.93 Billion

- CAGR (2026-2033): 23.9%

- North America: Largest market in 2025

- Asia Pacific: Fastest growing market

Key Companies & Market Share Insights

Several major players are contributing to the growth of the 3D printing market through strategies like expansion and partnerships:

- 3D Systems, Inc.: This U.S.-based technology company specializes in desktop 3D printing products, including printers, materials, software, and 3D scanners. They cater to industries like aerospace & defense, automotive, healthcare, and entertainment, focusing on the design and manufacture of complex parts with reduced lead time and cost.

- Materialise: A Belgium-based company that offers a range of software solutions, 3D printing services, and engineering services, Materialise serves industries such as healthcare, aerospace, automotive, and consumer goods, driving the adoption of desktop 3D printing technologies.

Key Players

- 3D Systems, Inc.

- Stratasys Ltd.

- Proto Labs, Inc.

- Materialise NV

- Nano Dimension Ltd.

- Shapeways, Inc.

- EOS (Electro Optical Systems) GmbH

- GE Additive

- HP Inc.

- Voxeljet AG

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion

The 3D printing market is poised for significant growth over the coming years, driven by advancements in technology, increasing demand for customization, and the integration of additive manufacturing into various industries. North America will continue to be a dominant player, while the Asia Pacific region is expected to experience the fastest growth. As innovations in hardware, software, and materials evolve, 3D printing is set to revolutionize manufacturing, providing more efficient, flexible, and cost-effective solutions across a wide range of industries.